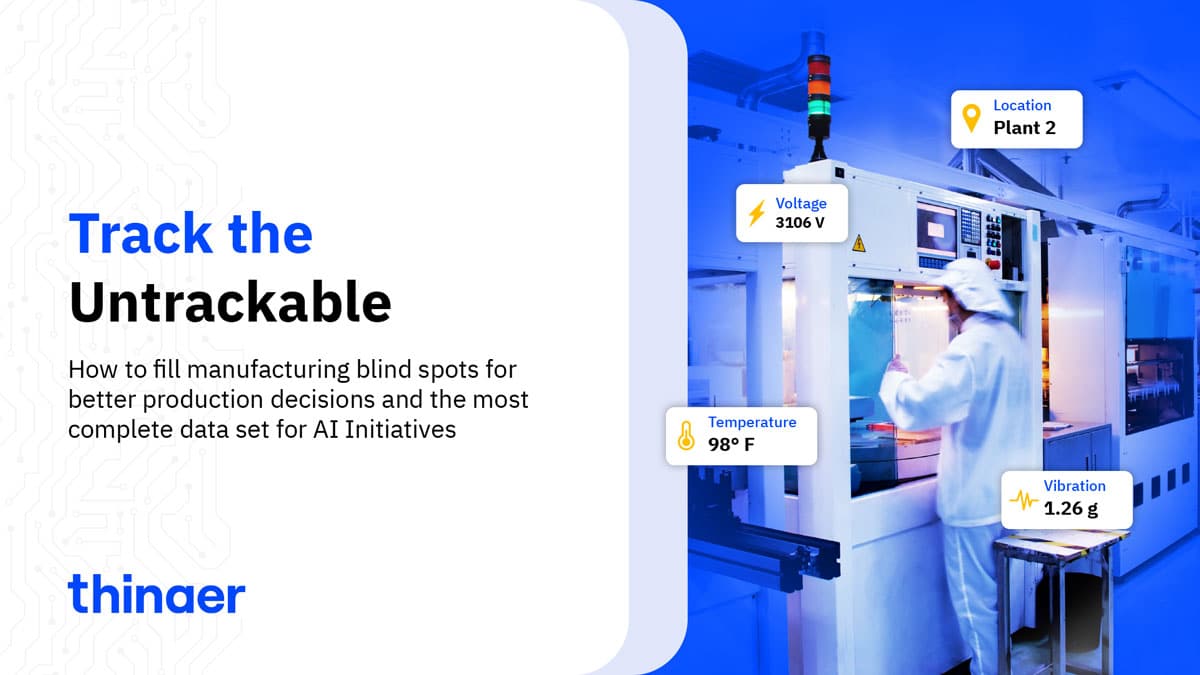

Fill Your Manufacturing Data Blind Spots

for better production decisions and the most complete data set for AI Initiatives

Empowering Industry 4.0 Smart Manufacturing

%

Digital Data Integration

Despite the promise of Industry 4.0, only a fraction of manufacturers (25%) have successfully integrated digital data across their operations, hindering the seamless flow of information envisioned for smart manufacturing.

%

Legacy Analog Equipment

The majority of manufacturers (65%) still grapple with legacy analog equipment, posing a significant barrier to achieving the frictionless exchange of data crucial for realizing the potential of Industry 4.0 and smart manufacturing.

%

Manual Processes

Despite the advancements in digital technology, a majority (75%) of manufacturers still rely on manual processes, presenting a formidable obstacle in bridging the gap between real-time operations and data-driven decision-making. This hampers the efficient flow of information critical for maximizing value creation in modern manufacturing organizations and supply chains.

Decision Making and AI Requires a Complete Data Picture

An incomplete data picture impacts:

- Production and operations decisions for efficiency, quality and profitability

- AI initiatives will skew decision making based on only available data

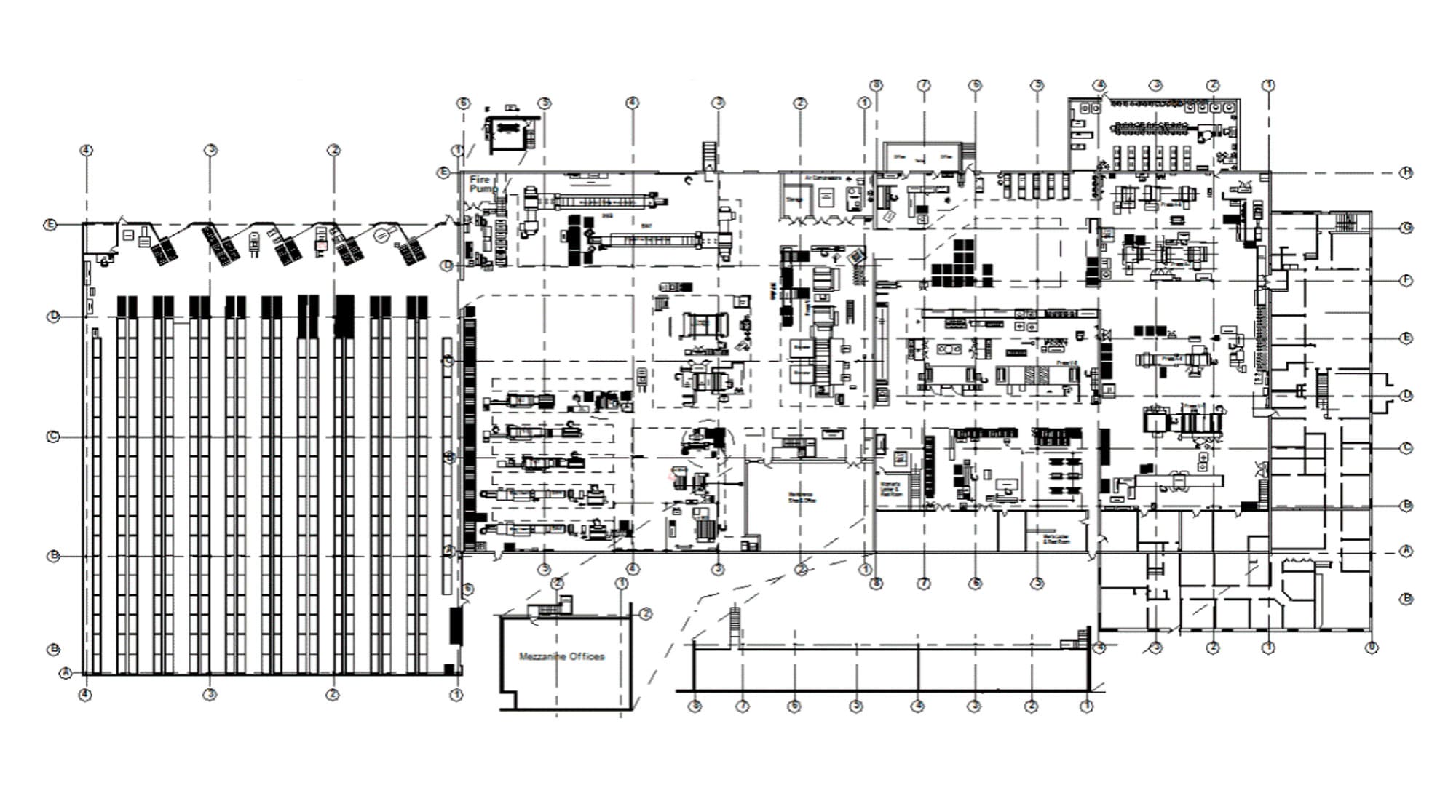

Manufacturing Digital Blind Spots are Pervasive

(click on colored headers to toggle overlays)

Connected

Equipment and processes already integrated with digital systems (ERP, MES, MOM, BI Tools), providing real-time data.

Connectable

Devices and systems capable of digital integration but currently standalone, requiring minimal modifications to become connected.

Non-Digital

Legacy equipment and processes that are either manual or analog, which do not currently generate digital data automatically. This includes both non-instrumented equipment (traditional analog) and manual processes requiring human intervention for data collection.

Digital data is the most precious commodity of every org today

Discover the keys to manufacturing success in our essential eBook. In just minutes, conquer challenges like blind spots and digital transformation. Learn about IIoT asset tracking, digital asset management, and the power of digital twins.

Thinaer Fills Manufacturing Data Blind Spots

Thinaer offers transformative solutions for asset and raw material tracking and the digital twin of any machine. Its automated system can be completely stand-alone and even air gapped where regulations dictate but has a secure intermediary approach for secure data sharing and integrating with ERP systems. Filling manufacturing data blind spots has never been easier.

Real World Use Cases

Making IIoT Work to Revolutionize Manufacturing

Creating a Factory of the Future for a Fortune 100 DoD Manufacturer generated $30 Million in ROI

Tracking Machine Utilization to Reduce Equipment Downtime for an Aerospace Manufacturer led to 15% less unscheduled equipment downtime

Precision monitoring raw materials to reduce waste for Manufacturing company resulted in 9% reduction in raw material waste

Find Your Blind Spots

Free 30-Minute Blind Spot Workshop

Discover how to gather data from IIoT, RFID, and even manual “blind spot” operations • Includes security tips • Learn benefits of tracking not just location, but real-time visuality into production • See how this data leads to smart predictions • Learn how to use AI to analyze your data • 11 techniques to uncover data in the 75% of your manufacturing that’s currently invisible • 5 ways to source the best transformative data partner • and more!

Thinaer Spotlight

The latest in Manufacturing Visibility

Supply Chain Health Requires Industry 4.0-Level Data

Back in 1735 Benjamin Franklin provided one of the most important reminders to leaders across any industry or discipline when he wrote that “an ounce of prevention is worth a pound of cure.” Turn...

The Realities Of AI In Manufacturing

According to the World Economic Forum, the global manufacturing AI market was worth over $3 billion in 2023 and is expected to increase to over $20 billion by 2028. The use cases grow each day with...

Classified eBook

Spending just 10 – 15 minutes with this eBook will help you to: Streamline asset management processes for government-owned organizations and company-owned classified assets. Leverage digital twins...