Manufacturing Transformation. Now.

with the benefits of Thinaer data solutions

Complete Data Picture

Real-time visibility into unconnected processes, assets, and equipment.

Better Strategies

Data-as-a-Service

Classified Management

Eliminate Blind Spots

Fast Implementation

Transform results with asset tracking, environmental monitoring, machine utilization, and digital twin technology, starting in just days.

Thinaer Transforms Manufacturing

Thinaer is transforming manufacturing with proven asset tracking, environmental monitoring, machine utilization, and digital twin technology. Our innovative, secure, and flexible IIoT platform gives manufacturers the ability to properly manage the digital blind spots that make up 75% or more of your operations. Real-time visibility into even the most unconnected processes, assets, and equipment fills in the gaps to inform strategic decisions that increase productivity, profitability, and compliance in sectors such as manufacturing, aerospace, defense, aviation, and consumer goods. This even includes architectures for formerly “impossible” areas, such as air-gapped and classified areas.

How Thinaer Works for smarter decisions

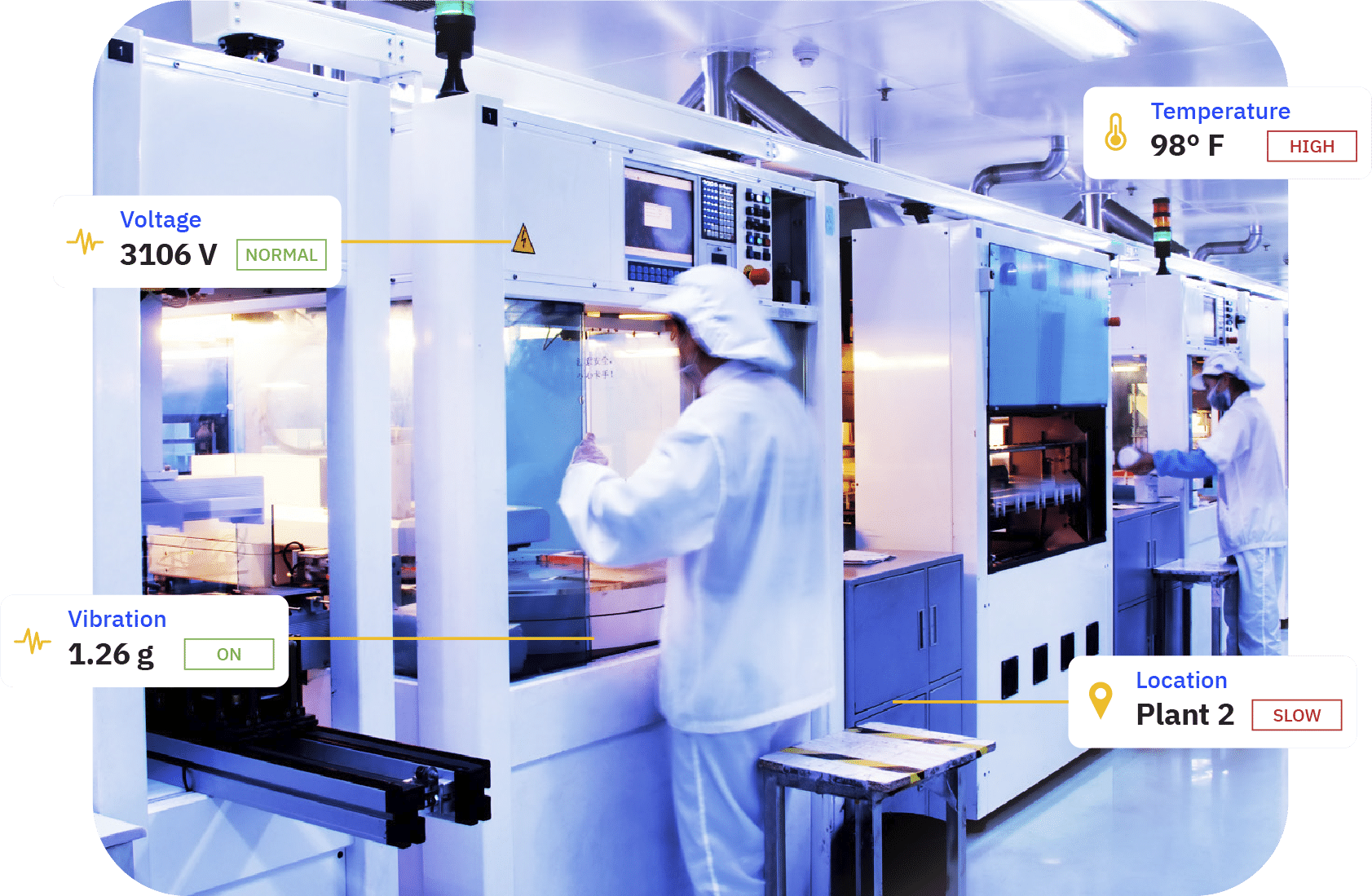

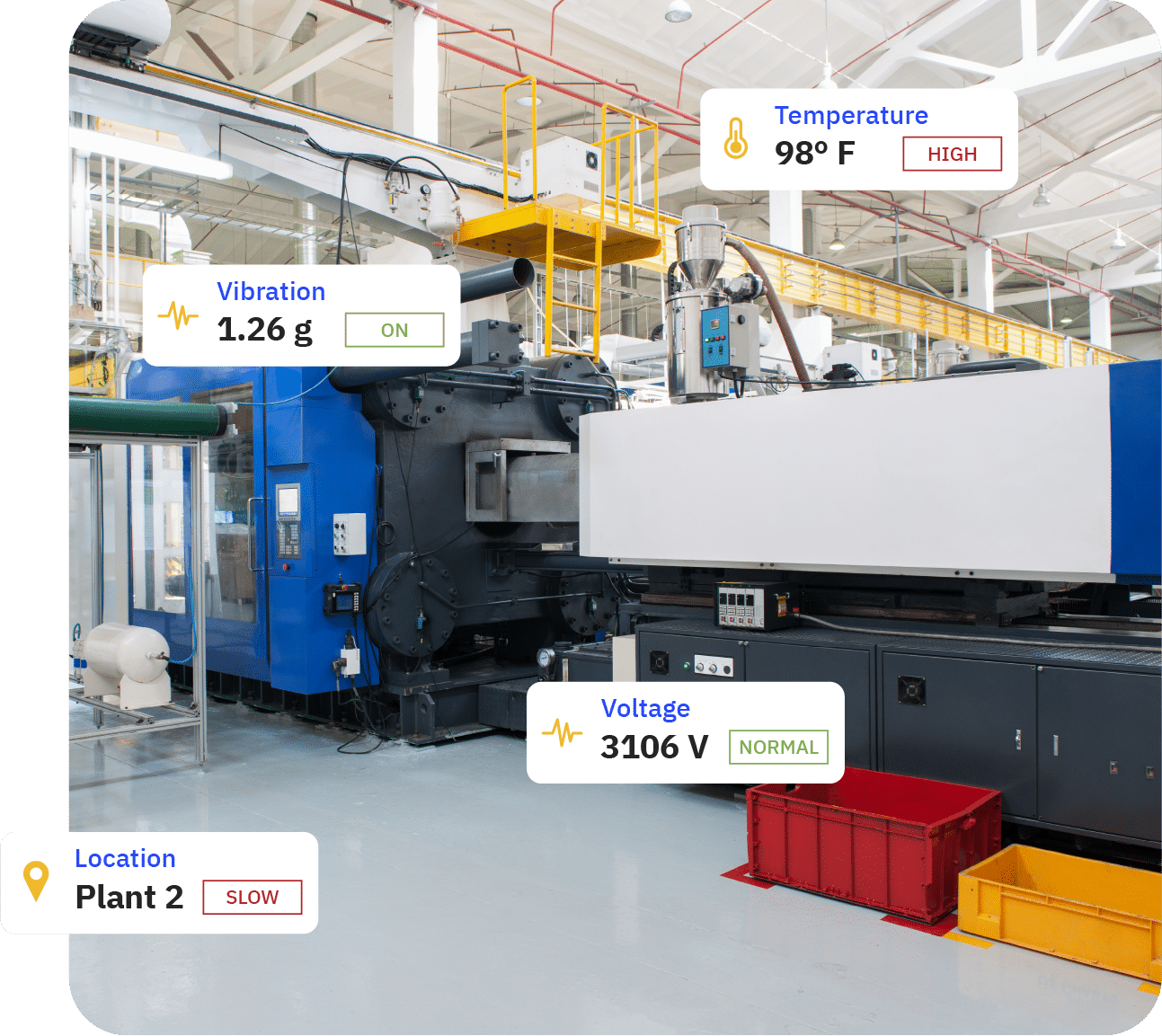

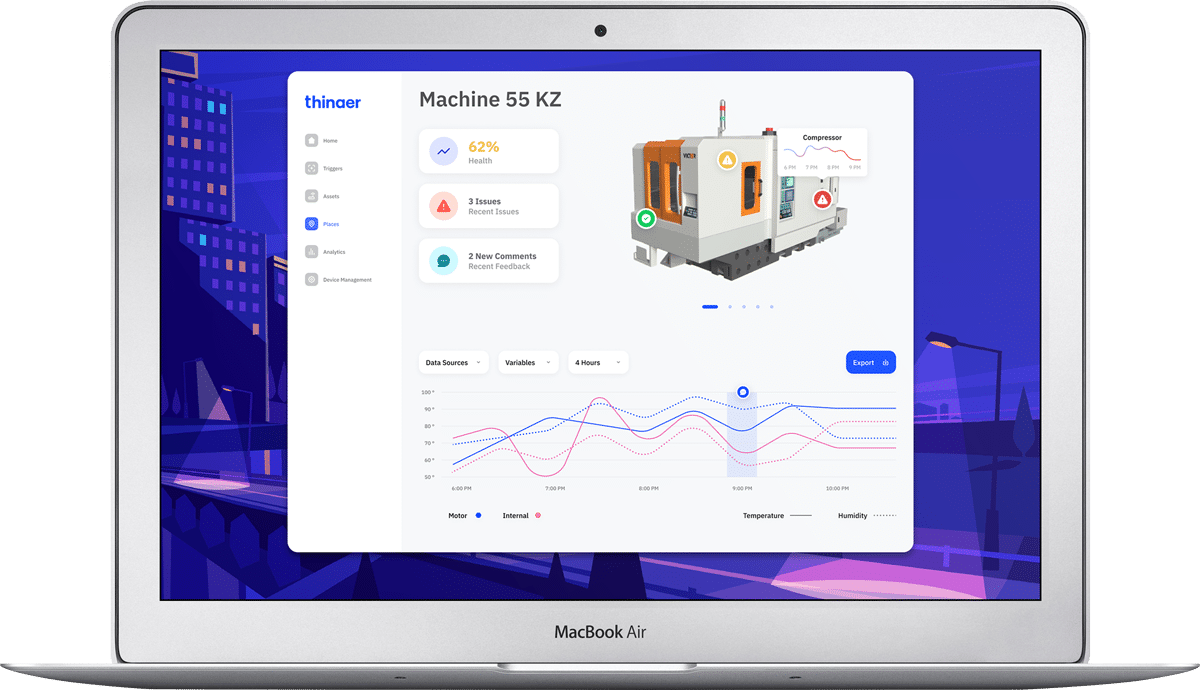

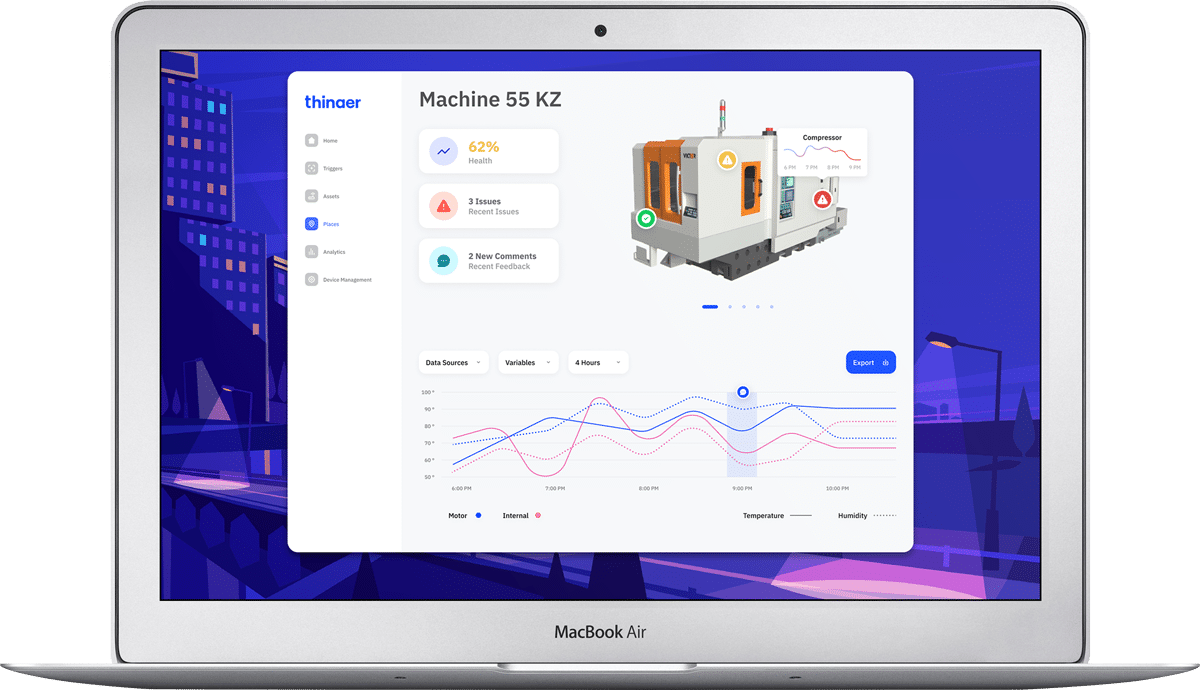

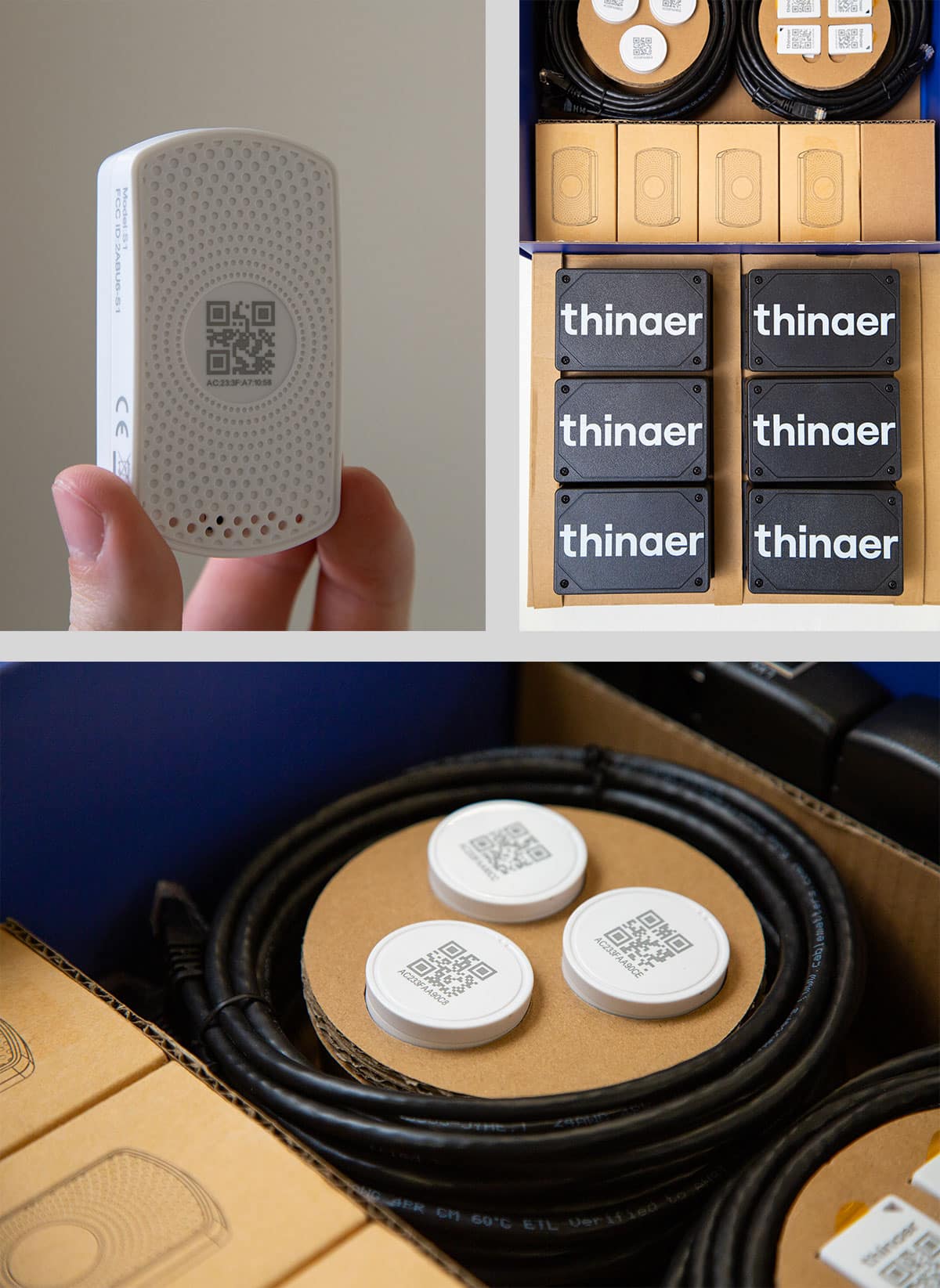

Thinaer bridges the gap between IT and Operations. Thinaer collects millions of data points from the broadest range of sensors — yours and ours. IIoT beacons and sensors are attached to physical assets and equipment then send data to gateways. That data is sent to the Thinaer platform, which ingests and standardizes the data, supplying it for APIs, notifications, triggers and alerts.

A digital twin is enabled for deeper analysis and predictions. You can dig deep in the data, with visualizations, a location map, smart alerts, equipment comparisons, and more with the Thinaer Sonar™ application or your own analytical tools.

Easy implementation with data setups beginning in just days

Thinaer’s implementation process is streamlined for speed and simplicity, delivering results within days. Benefit from our expert guidance, comprehensive knowledge base, and responsive support for a seamless transition.

With out-of-the-box solutions and step-by-step tutorials, setup is straightforward and efficient. Our dedicated project management ensures smooth deployment, empowering you to optimize operations quickly and effectively. Experience the ease of Thinaer’s implementation process and unlock immediate value for your organization.

Digital data is the most precious commodity of every org today

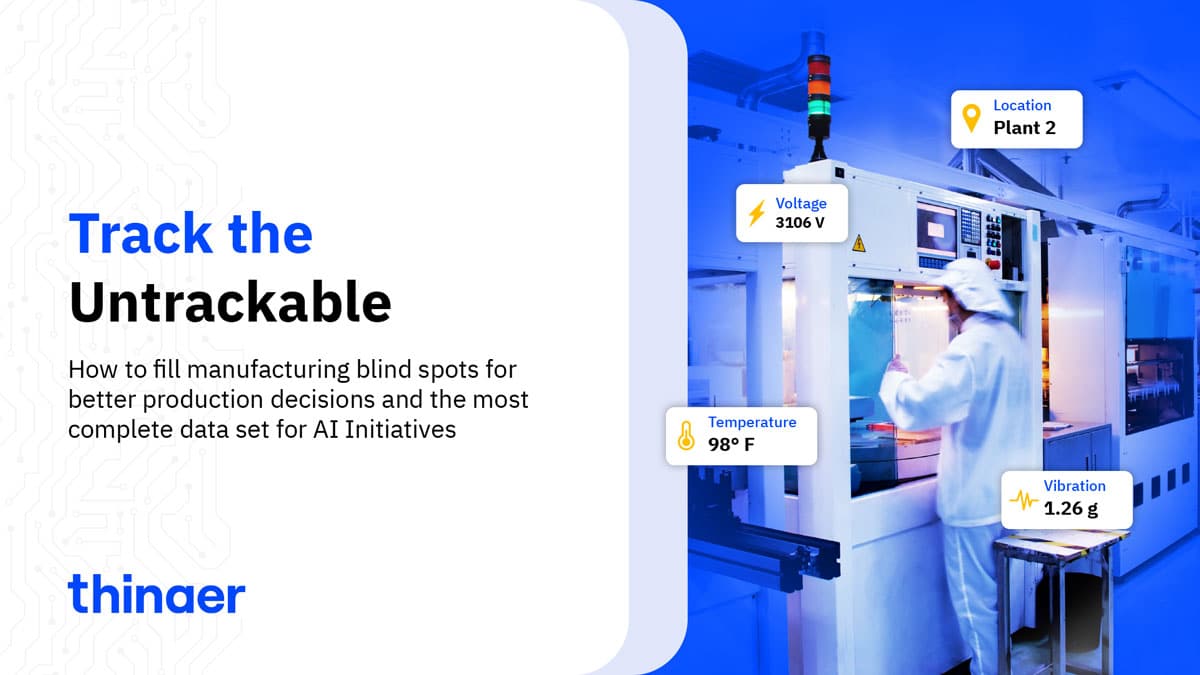

Discover the keys to manufacturing success in our essential eBook. In just minutes, conquer challenges like blind spots and digital transformation. Learn about IIoT asset tracking, digital asset management, and the power of digital twins.

Our Solutions in Action

Making IIoT Work to Revolutionize Manufacturing

Revolutionizing Operations for a Fortune 100 DoD Manufacturer

Increased Uptime in Aerospace Manufacturing with Predictive Analytics

Eco-Smart Manufacturing That Increases Profits

Thinaer Spotlight

The latest in Healthcare & Hospital Visibility

Supply Chain Health Requires Industry 4.0-Level Data

Back in 1735 Benjamin Franklin provided one of the most important reminders to leaders across any industry or discipline when he wrote that “an ounce of prevention is worth a pound of cure.” Turn...

AI Analytics In Manufacturing: Top Strategies From Tech Experts

1. Gain Full Visibility Into Production Processes AI-powered analytics help manufacturers make better decisions. For AI initiatives to be successful, manufacturers must collect sufficient data....

Classified eBook

Spending just 10 – 15 minutes with this eBook will help you to: Streamline asset management processes for government-owned organizations and company-owned classified assets. Leverage digital twins...

Find Your Blind Spots

Free 30-Minute Blind Spot Workshop

Thinaer gives you a roadmap to connectivity and helps you identify your blind spots, walk you through how to look over your factory floor, identify what areas and equipment are collecting data manually, what’s still analog, and what is connected.