The Missing Link to your Digital Thread

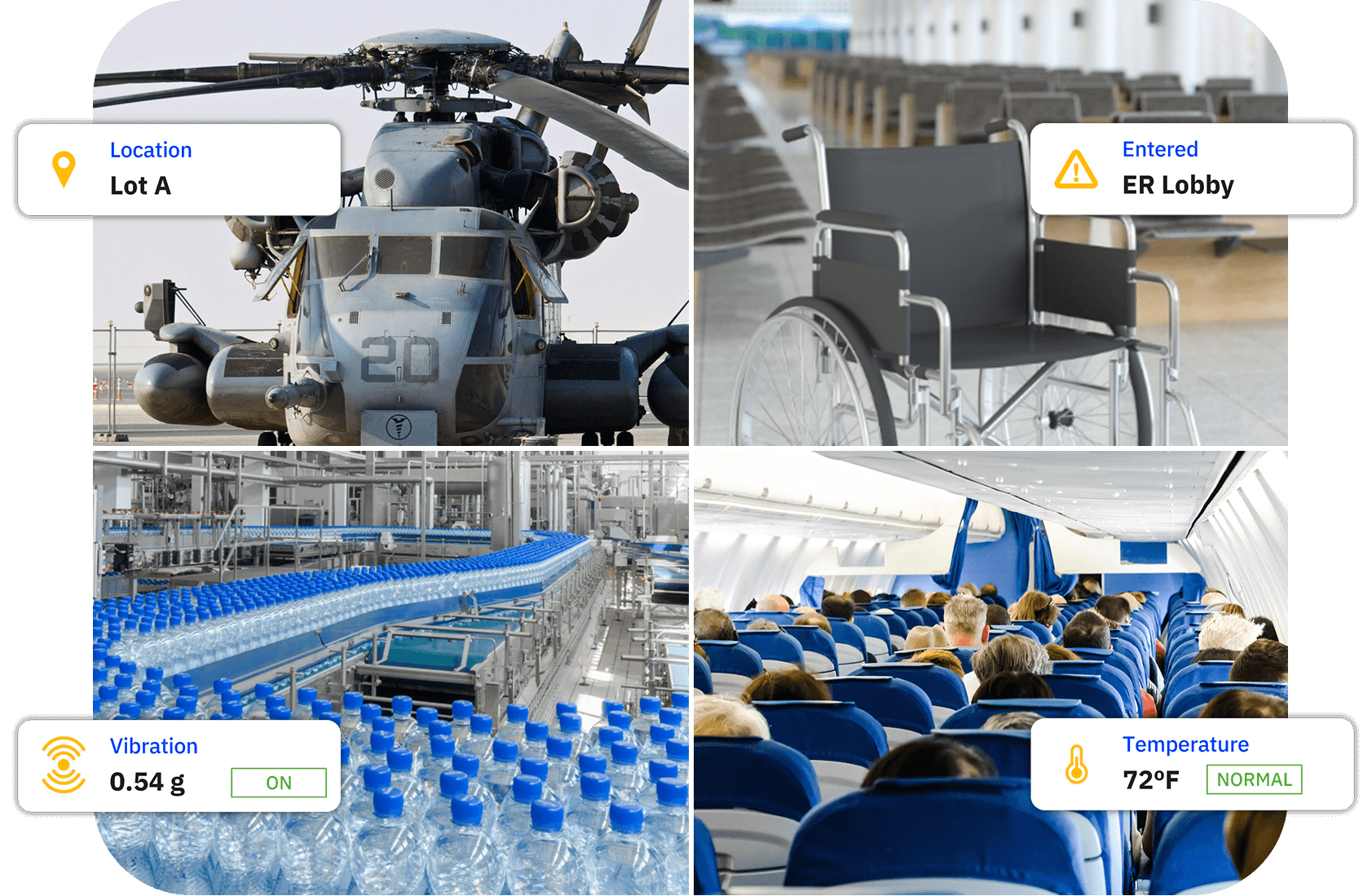

Off-the-shelf Iot Sensors & No-Code Platform

With end-to-end IoT integration and digital twin for any industry

Complete Data Picture

Real-time visibility into unconnected processes, assets, and equipment.

Better Strategies

Modeling with digital twins allows strategic prediction and planning.

Data-as-a-Service

Full-coverage data for strategic AI modeling, analysis and predictions.

Classified Management

Data architecture and air-gapped solutions safe for classified areas

Eliminate Blind Spots

75%+ of your data is hidden in digital blind spots. Not anymore.

Fast Implementation

Thinaer makes it easy, with implementations beginning in just days.

Let’s Find Your Data Blind Spots

Claim Your Free 15-Minute Session

Thinaer gives you a roadmap to connectivity and helps you identify your blind spots, walk you through how to look over your factory floor, identify what areas and equipment are collecting data manually, what’s still analog, and what is connected.

Begin in Just Days.

Deploy Our IoT Devices

Thinaer’s implementation process is streamlined for speed and simplicity, delivering results within days.

Benefit from our expert guidance, comprehensive knowledge base, and responsive support for a seamless transition.

With out-of-the-box solutions and step-by-step tutorials, setup is straightforward and efficient.

Our dedicated project management ensures smooth deployment, empowering you to optimize operations quickly and effectively. Experience the ease of Thinaer’s implementation process and unlock immediate value for your organization.

Thinaer Updates

The latest in IoT & Connected Operations Visibility

Jeff Winter on Industry 4.0: Actionable Strategies for Manufacturing’s Digital Future

Industry 4.0 demands clear guidance amid rapid smart manufacturing advancements. Jeff Winter, Vice President of Business Strategy at Critical Manufacturing and a recognized Industry 4.0 authority,...

Thinaer Launches Sonar 6.0.0, Delivering Breakthrough Geospatial Mapping and Enhanced Operational Insights

RICHARDSON, Texas, March 5, 2025 /PRNewswire/ -- Thinaer today announces the release of Sonar 6.0.0, a transformative upgrade that sets a new standard in geospatial insights and overall platform...