Key Highlights

- The manufacturing industry is increasingly using the Internet of Things (IoT). It helps to improve operations, boost productivity, and support data-based decisions.

- The iot sensors market is expanding rapidly as more companies adopt smart devices.

- IoT devices, such as sensors, robots, and smart gadgets, gather and share data in real-time, providing useful insights into how things are made.

- With predictive maintenance from IoT, companies can spot possible equipment failures before they happen, reducing downtime and maintenance costs.

- IoT also helps improve quality control. It monitors production processes and finds mistakes, improving product quality and increasing customer satisfaction.

- IoT is changing traditional manufacturing into smart factories. These smart factories use automation, share data, and have systems that work together.

The manufacturing industry is changing because of digital transformation at the hands of manufacturing IoT devices, which are essential in this change. They allow machines, systems, and processes to connect easily. This connection is changing how goods are made, tracked, and controlled. Smart sensors on the factory floor and linked supply chains help manufacturers work better. They also improve operations and allow for decisions based on data.

Exploring the Basics of IoT in Manufacturing

In simple terms, IoT in manufacturing means a group of connected devices, sensors, and software. These systems share and exchange data, improving many parts of the production process. By using these connections, manufacturers can see how their machines run, the conditions around them, and how materials move. This information helps manufacturers make smart choices and boost their overall operations.

IoT helps gather and analyze data while also automating tasks. This support allows manufacturers to work more efficiently and effectively. With this system, they can see everything. It leads to less downtime and better product quality, creating a more robust and flexible manufacturing environment.

Defining IoT in Manufacturing

The Internet of Things (IoT) in manufacturing means a network of physical objects. These objects have sensors, software, and connectivity. This setup helps them collect and share data. Often, this is called the Industrial Internet of Things (IIoT), which refers to how we do, track, and improve manufacturing operations.

The importance of IoT in modern manufacturing is clear. It gives real-time visibility into every part of the production process. Manufacturers can see how well their equipment works by collecting data from machines, sensors, and inventory systems. They learn about production efficiency and how resources are used. This information helps businesses make good decisions, spot problems early, and improve operations for better productivity and cost savings, ultimately benefiting the bottom line.

In addition, IoT improves teamwork and communication among different departments. With real-time data, teams can work well together. They can quickly react to changing needs and manage possible issues or delays. This connection makes companies more nimble. It helps manufacturers meet changing market demands and customer requirements smoothly.

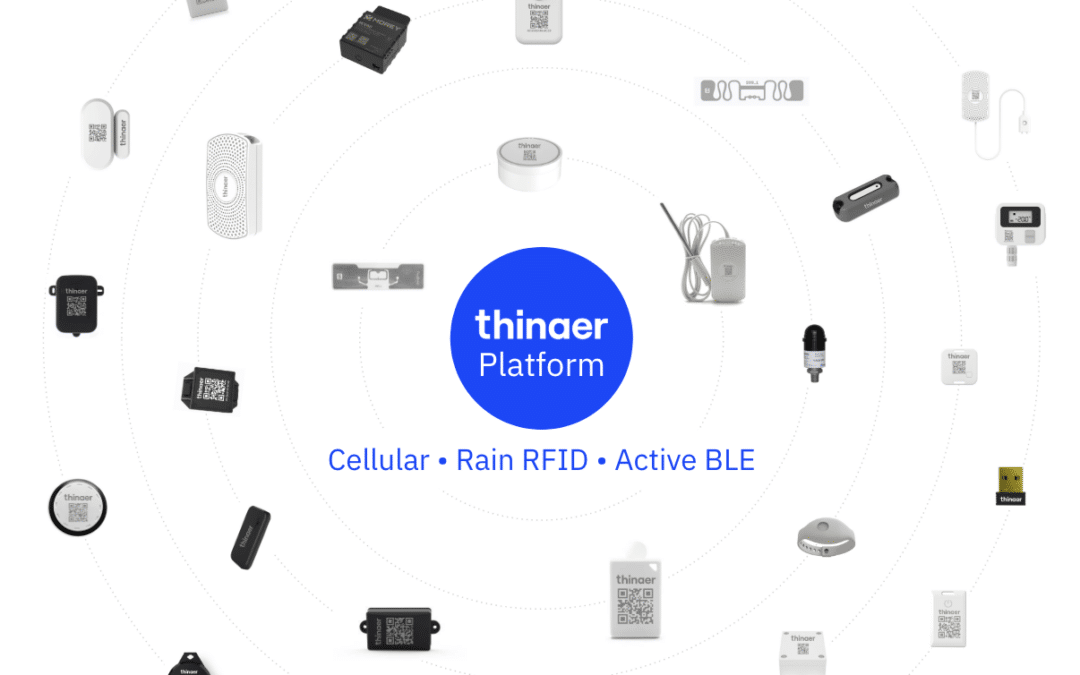

Overview of IoT Devices Used in Manufacturing

IoT sensors, including vibration sensors, are key for collecting data in smart manufacturing. They can track many things like temperature, pressure, vibration, and energy use. This information helps understand machine health, environment, and how well processes work. By getting and sending this data, IoT sensors help with monitoring and checking on machines right away. This lets manufacturers improve processes, see any future issues, and make machines work better.

Smart sensors, including motion sensors, a type of IoT device, can do more than just gather data. They can also analyze and process information at the spot. This speeds up decision-making and cuts down the need for central systems. These clever sensors can find problems, send alerts, and even start actions based on current data. This makes manufacturing smarter and quicker.

Besides sensors, industrial IoT devices in manufacturing include many technologies. This covers things like industrial robots, RFID tags, smart cameras, medical devices, and wearable devices for workers. These connected devices create a complete network. They allow for data sharing, communication, and automation during different steps of the production process, including handling raw materials, quality control, and logistics. Moreover, wireless IoT sensors and remote IoT sensors are becoming increasingly popular for their ease of deployment in hard-to-reach areas.

The Evolution of Manufacturing with IoT

The use of IoT represents an important change from old manufacturing methods to new ones that focus more on data and connection. As factories start to use digital transformation more, IoT is leading this change. It helps create smart factories with automation, real-time data analysis, and better connections.

This change comes with many advantages. These include better production efficiency, less downtime, higher product quality, and safer working conditions. By using IoT, manufacturing companies can improve how they work. They can stand out from their competitors and keep up with the changing needs of today’s market.

From Traditional Practices to Smart Factories

From tasks that require a lot of effort and separated information to connected systems and instant insights, IoT is bringing in a new time for smart manufacturing. This change, championed by the chief innovation officer, is transforming old practices by linking machines, processes, and people in ways we couldn’t have imagined before. It is leading to higher efficiency, better productivity, and more innovation.

Smart manufacturing, driven by IoT, shows the smooth movement of data throughout the production process. Sensors and smart devices placed in machines gather real-time information on how they are working, their output, and the conditions around them. This data is analyzed to improve processes, foresee possible problems, and make wise choices that boost equipment efficiency and decrease downtime.

Also, IoT helps teamwork and communication in the manufacturing world. Sharing data in real-time allows different departments, like production, quality control, and logistics, to work together better. They can respond more quickly to changes and tackle potential issues or delays ahead of time.

The Impact of Industry 4.0 and IoT

Industry 4.0 is all about adding digital technologies to manufacturing. It mainly uses IoT to connect machines, systems, and data. This change is reshaping the manufacturing market. It brings new chances for automation, better data analysis, and improving processes. This leads to better efficiency, productivity, and competitiveness.

Using IoT in Industry 4.0 is not just about gathering data. It’s about using that data to make smart choices, enhance processes, and drive new ideas. Getting real-time insights into how machines work, the efficiency of the production line, and how materials flow helps manufacturers see problems, cut waste, and increase production output.

By using IoT, manufacturers can adapt to changes in the market, respond faster to customer needs, and stay ahead of the competition. Adding IoT in Industry 4.0 is not just a tech upgrade. It’s a smart move for manufacturers who want to succeed in a world that is more data-driven and connected.

A Beginner’s Guide to Incorporating IoT in Manufacturing

Incorporating IoT into your manufacturing processes can be easy. Start by identifying your specific needs and choosing the right IoT solutions. This way, you can begin with focused implementations that fix important problems or help improve certain areas. By looking at practical use cases and slowly expanding your IoT setup, you can gain big benefits without disturbing your current operations.

Working with experienced IoT providers can make the integration process smoother. They can help you with implementation, data analysis, and ongoing support. By being strategic and aiming for constant improvement, you can use the power of IoT to make your manufacturing processes better and stay ahead in today’s tough market.

Identifying the Need for IoT in Your Manufacturing Process

Before you start using an IoT solution, it’s important to know your manufacturing process well. Look for the areas where IoT can really help you. Check your current operations and find the problems. Set clear goals for what you want to achieve with IoT. You might want to boost production efficiency, cut down on downtime, improve product quality, or make the supply chain easier to see.

After identifying the areas that need improvement, look into IoT use cases that match your goals. Find out how other manufacturers in your industry have used IoT to solve similar issues. Think about what data you need to gather, the right sensors or devices to use in your space, and how you will analyze the data to get useful insights.

By matching your specific needs with the right IoT solution, you can make your implementation more focused and effective. This will help you get the most out of your IoT investment and reach your targets. This plan allows you to begin with small, easy projects and then expand your IoT setup as needed.

Essential IoT Devices and Tools for Smart Manufacturing

Smart manufacturing depends on different IoT devices that work together. They collect, send, and analyze data. This helps with visibility, automation, and making better decisions. Some key IoT devices include sensors to check machine health and environmental conditions. RFID tags help with asset tracking. Smart cameras are used for quality control and process improvement.

Besides these main devices, there are software tools and platforms, including GovCloud, that are really important. They manage and analyze the data from the IoT ecosystem. These tools include cloud-based platforms for storing and processing data and software for advanced analytics. They help find trends, predict problems, and provide useful insights. A strong network, such as high-speed Wi-Fi or 5G, is necessary for smooth data flow and communication among the devices in smart manufacturing.

Choosing the right IoT devices and software tools depends on your specific manufacturing needs, goals, and budget. Working with experienced IoT solution providers can help you figure out the best technologies for your needs and create a solid smart manufacturing plan that fits with your business goals.

Step 1: Assessing Your Current Manufacturing Infrastructure

Before starting with IoT integration, check your current manufacturing setup. Make sure it is ready for this technology. Look at your current equipment, communication methods, data management systems, and the skills of your workers. This helps find any gaps that need fixing. It’s important to assess how well your systems can collect and analyze data. This way, you know if they can handle the large amounts of big data from IoT sensors.

Examine how well your current machines and equipment can work with IoT sensors. Think about things like how data is sent, power needs, and conditions in the environment. This ensures smooth integration and good data collection. If your setup uses old systems, you may need to look for ways to modernize or find fixes that let IoT devices work together.

By checking your manufacturing setup thoroughly, you can spot any problems early. This lets you plan any upgrades or changes needed for successful IoT integration. Taking this step ensures a smoother transition. It reduces disruptions to your current work and improves the chances of doing IoT well.

Step 2: Planning the Integration of IoT Devices

After you check your setup, make a detailed plan to add IoT devices into your manufacturing process. This plan should state your goals. You should choose the right IoT devices and software and set a clear timeline for implementation. Think about how adding IoT fits with your business models and digital transformation strategy.

Find the most important parts of your manufacturing process where IoT can help the most. This could mean focusing on specific production lines, equipment, or steps that will gain the most from real-time data monitoring and analysis. Focus on these areas for your first rollout, and then increase your IoT network step by step as needed.

Working together with your IT team, operational technology staff, and possible IoT solution providers is very important for a successful integration. Clearly state roles and responsibilities. Set up communication lines and make sure everyone understands the project goals, timelines, and expected results. This teamwork will help make the integration smoother and create a stronger IoT ecosystem.

Step 3: Implementing IoT Devices

When setting up IoT devices, focus on proper installation and configuration. This is important for getting the best performance and accurate data collection. Think about where to place the sensors, consider environmental factors, and use the right data transmission methods. This will help you get reliable data while reducing any signal issues. Working with an experienced IoT solutions provider can make the process easier and ensure your devices fit well into your existing production line.

After installation, test the IoT devices to check how well they work and their accuracy. Adjust sensors to make sure they collect data correctly within the needed limits. Run small tests to confirm the IoT system works properly before proceeding with a larger rollout. This method lets you make changes based on any problems and improve your data collection approach.

Keep an eye on the performance of your IoT devices regularly. This helps keep your equipment running well and your data accurate. Create a maintenance plan which includes checking the devices, cleaning them, and recalibrating when needed. This will help prevent any issues and ensure your IoT system stays reliable and effective for a long time, boosting your manufacturing operations.

Step 4: Analyzing Data Generated by IoT Devices

The real value of IoT in manufacturing comes from the ability to find useful insights in the large amounts of data from connected devices. You should use strong data analytics tools to process, visualize, and analyze the machine data from your IoT system. This could mean using cloud-based platforms, edge computing, or both, based on what you need and how much data you have.

Focus on finding important patterns, trends, and issues in the IoT data. You should figure out the key performance indicators (KPIs) that match your business goals, like equipment efficiency, production output, or energy consumption. Make dashboards and visualizations that show these insights clearly to the right people. This will help everyone in the organization make decisions based on data.

Make sure to regularly review and improve your data analysis methods as you get more IoT data and better understand your manufacturing processes. This ongoing method will help you find new insights, improve your operations, and make the most of your IoT investment over time.

Step 5: Continuous Improvement and Upgradation

IoT implementation isn’t just a one-time task. It is a journey that needs continuous improvement. You should check how your IIoT system is performing regularly. Collect feedback from users and find areas where you can improve. Stay updated on new technologies and best practices to keep your IoT applications effective.

As your manufacturing operations change or new business needs come up, you need to change your IIoT setup too. This may mean adding new devices, expanding your network, or upgrading your data analytics. Being flexible and able to adapt is important. This helps maximize the value of your IoT investment and keeps you competitive as the manufacturing world changes.

Also, create a culture where decisions are driven by data in your company. Promote teamwork between IT staff, data analysts, and operations teams. This collaboration helps make sure that insights from your IIoT system lead to real improvements. Working together allows your team to use data for solving problems and improving manufacturing operations over time.

Key Benefits of IoT in Manufacturing

IoT helps connect machines, analyze data, and automate business processes in the physical world. This offers many benefits for manufacturers. They can see improvements in production efficiency and predictive maintenance. They also get better quality control and supply chain visibility. IoT helps businesses make their operations smoother and stay ahead in today’s fast-changing market.

When manufacturers use IoT, they can improve their profits and build a more flexible and innovative manufacturing environment. This data-based approach helps companies adapt to changing market needs, better meet customer expectations, and work toward long-term growth.

One big benefit of IoT in manufacturing is that it can make operations run better and faster. Manufacturers get useful information by gathering real-time data on how machines work, how materials move, and what the environment is like. This information helps them make processes smoother, reduce waste, and use resources better. With this data, manufacturers can spot and fix slow points, improve how the production line works, and boost overall equipment effectiveness (OEE).

IoT also helps with predictive maintenance, reducing downtime and lower maintenance costs. Sensors can check the health of machines and warn technicians about possible problems before they become expensive breakdowns. This lets manufacturers move from reacting to problems to proactively planning repairs during breaks and making their equipment last longer.

In addition, IoT helps with managing inventory more effectively. It gives a clear view of stock levels, materials use, and what’s happening in the supply chain. Manufacturers can keep their inventory at the right level, lower waste from not using materials in time, and reduce waiting times caused by material shortages. This all leads to better production efficiency and lower costs.

Achieving Predictive Maintenance and Reduced Downtime

Predictive maintenance is changing the game in manufacturing. IoT uses real-time data from sensors to foresee equipment failures before they happen. This differs from traditional maintenance, which reacts to problems and often leads to costly downtimes and repairs. Predictive maintenance helps manufacturers plan repairs during scheduled downtimes. This keeps production running smoothly and helps equipment last longer.

By looking at historical and real-time information like vibration, temperature, and energy consumption, machine learning can find small issues that could mean a failure is coming. Finding problems early means repairs can happen on time. These repairs are usually less invasive and cheaper, which helps lower maintenance costs and reduces unplanned downtime.

Switching to predictive maintenance makes equipment more reliable and lasts longer. It also keeps workers safer by reducing the chances of unexpected breakdowns. Predictive maintenance boosts productivity and customer satisfaction by cutting down downtime and helping maintain a steady production flow. Customers receive their orders on time and enjoy better product quality.

Quality Control and Compliance

IoT plays a vital role in improving manufacturing quality control. By using sensors in different parts of production, companies can keep track of important things like temperature, pressure, and sizes in real time. This helps them check quality constantly and find any issues early.

Automated alerts tell operators about potential quality problems so they can fix them right away. This helps lower defects and ensure consistent product quality. Real-time checking and acting quickly also help reduce waste from faulty products and improve customer satisfaction.

Also, IoT helps manufacturers meet industry rules and standards by providing data that can be checked. By collecting and saving sensor data, companies can show that they follow safety rules, environmental laws, and quality standards. This data-driven way makes it easier to report on compliance, lowers the chance of fines, and boosts brand reputation.

Enabling Real-Time Decision Making

Real-time decision-making is an important part of smart manufacturing. IoT, or the Internet of Things, helps make this possible. It gives quick access to production data, machine health, and other conditions, allowing operators, managers, and executives to make good choices quickly. With real-time data analytics dashboards, manufacturers can quickly improve processes, use resources wisely, and solve problems before they worsen.

Being able to respond quickly is very important today. Production needs and customer expectations can change in a heartbeat. By giving decision-makers real-time information, IoT helps them make data-based choices. This leads to better problem-solving, smart resource use, and improved efficiency.

Additionally, insights from analyzing real-time data support ongoing improvements. By spotting patterns and trends, manufacturers can make their processes better over time. This helps them boost efficiency, lower costs, and enhance the quality of their products or services.

Addressing Challenges in IoT Adoption

The benefits of IoT in manufacturing are clear, but using this technology comes with some challenges. Companies often face issues like data security, difficulties with technical setups, and the need to see a good return on investment. Still, by understanding these challenges and using strong strategies, manufacturers can overcome these problems and take advantage of the huge benefits of IoT in their operations.

Solutions include implementing strong security measures, ensuring systems can work together, and focusing on smart IoT setups that meet specific business needs for defense and dod manufacturers. By dealing with these issues directly, manufacturers can smoother the move to an IoT-ready factory and enjoy the benefits of a more efficient, data-driven, and competitive business.

Ensuring ROI with IoT Implementation

While IoT offers many benefits for manufacturing, getting a good return on investment (ROI) needs careful planning and smart steps. Start by clearly setting your business goals. Next, find key areas where an IoT solution can make real improvements. Then, pick the right technology that fits your needs and budget.

Focusing on use cases that can save costs, improve operational efficiency, or increase revenue is essential for a better ROI. For example, working on predictive maintenance and conditional monitoring can help reduce downtime. Improving energy consumption and product quality by using environmental monitoring with real-time monitoring usually gives quicker and clearer returns.

Keep checking and measuring how well your IoT solutions work against the goals you set. This will help you track ROI. With this information, you can decide to grow successful projects, change plans for areas that aren’t doing well, and make sure your IoT solution keeps providing value over time.

Future Trends in Manufacturing IoT

The world of IoT in manufacturing is always changing. New trends like adding artificial intelligence, using private 5G networks, and more edge computing are setting the path for smart manufacturing. These changes will lead to smarter and more connected production methods.

As technology improves, we will see more innovations and use cases for IoT in manufacturing. This will help businesses improve their operations, improve product quality, keep workers safe, and quickly meet market needs. For manufacturers, using these new advancements is important to stay ahead in the future.

Leveraging AI and Machine Learning

The blend of AI, machine learning, and IoT opens a new chapter for smart manufacturing. By using machine learning to analyze data from IoT devices, manufacturers can find hidden trends, forecast future needs, and better understand their work than ever before. This helps businesses improve their operations and boost productivity.

For instance, AI-driven predictive maintenance does more than just find potential problems with machines. It also suggests the best times to maintain equipment and how many spare parts to keep. This cuts down on costs and improves maintenance. Additionally, machine learning can help schedule production, change machine settings in real-time as materials vary, and customize products based on what customers want. This all leads to better quality, less waste, and more efficient outcomes.

As AI and machine learning keep growing in the aviation industry, we will see more exciting uses in aerospace manufacturing. These include robots that work on their own, production lines that optimize themselves, smart supply chains, and design choices driven by data. AI and IoT will lead the way in making aerospace manufacturing smarter, more flexible, and better at meeting the changeable market demands.

In conclusion, using IoT devices in manufacturing is essential for keeping up in the industry. These devices help improve how operations run and allow for quick decision-making. The benefits of IoT are significant. If you follow the beginner’s guide and tackle issues like data security and technical setup, you can bring IoT into your manufacturing processes successfully. Embracing future trends such as AI, machine learning, and 5G will change manufacturing operations even more. Stay ahead by using IoT technologies to transform your manufacturing into smart factories.

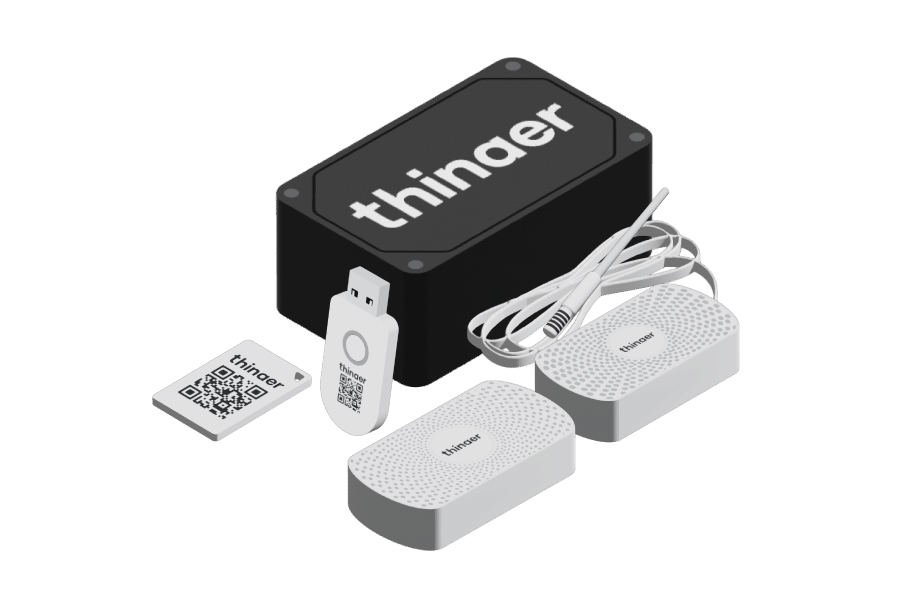

Work With Us

Thinaer is a solutions partner in IoT integration for manufacturing across multiple industries. Schedule a call with one of our team members to learn more about how we can help connect your unconnected spaces and provide end-to-end digital transformation of your spaces.

Frequently Asked Questions

What are the First Steps in Introducing IoT into My Manufacturing Process?

The first steps to smart manufacturing include finding areas that need improvement and figuring out useful use cases for IoT sensors. It’s also important to check if your current setup is ready for IoT integration. Working with skilled IoT providers can help you understand the process and create solutions just for you.

How Can IoT Devices Improve Worker Safety in Factories?

IoT devices improve workplace safety. They use smart sensors to find dangerous conditions such as gas leaks, high temperatures, or equipment issues. Wearable devices can track worker health and send alerts during emergencies. This helps create a safer work environment.

What is the Role of Data Analytics in IoT for Manufacturing?

Data analytics is important for getting useful information from the large amounts of data IoT devices create. By looking at this “big data,” manufacturers can improve production. They can also predict equipment failures, find quality problems, and make data-based decisions to improve operations.

Can Small and Medium-Sized Enterprises Benefit from IoT?

SMEs in the manufacturing sector can gain a lot from using IoT. While they might need to spend money initially, IoT solutions can help them save costs later. They do this by making things run more smoothly, cutting down on work stoppages, and using resources better. This makes IoT beneficial and vital for businesses of all sizes.

What Future Innovations Can We Expect in Manufacturing IoT?

The future of manufacturing IoT looks bright. There will be more changes in the way we do things. The market size is expected to grow at a tremendous annual growth rate. We can expect to see more use of AI, edge computing, and advanced analytics. This will lead to smarter and more independent manufacturing processes driven by data.