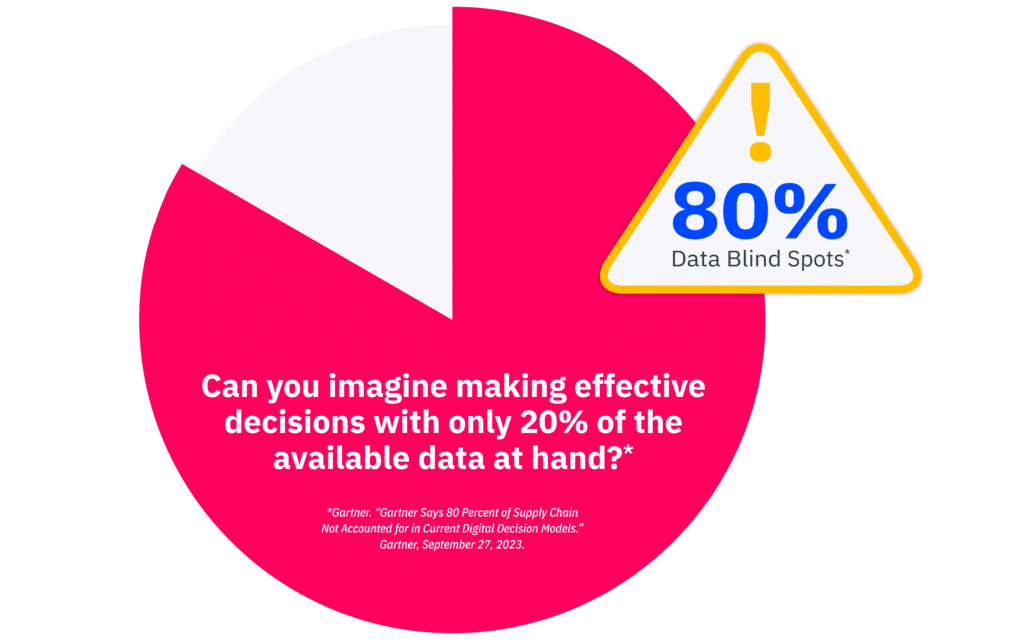

As the renowned management consultant Peter Drucker famously said, “You can’t manage what you can’t measure.” This timeless wisdom is especially relevant in today’s industrial landscape, where over 80% of operations remain unconnected, resulting in significant digital data blind spots. These blind spots hinder companies from achieving optimal efficiency, agility, and competitiveness. So, why do these gaps exist, and how can companies overcome them? In this blog post, we’ll explore the top reasons your operations are in the dark and provide actionable steps to fix them.

Top Reasons Your Operations Are in the Dark

- Legacy Equipment Many industries still rely on older machinery and equipment that were not designed with connectivity in mind. These legacy systems often lack the necessary interfaces to communicate with modern digital platforms, making integration a complex and costly endeavor.

- Cost Concerns The perceived high costs of upgrading or replacing existing infrastructure can be a significant barrier. Companies may hesitate to invest in new technology without clearly understanding the potential return on investment.

- Data Silos Operations frequently involve multiple standalone systems that do not communicate with each other. This fragmentation leads to isolated data pockets, making it challenging to achieve a unified view of the entire operation.

- Technical Expertise A lack of in-house expertise in implementing and managing IIoT (Industrial Internet of Things) solutions can deter companies from pursuing connectivity projects. Without the right skills, the prospect of digital transformation can seem daunting.

- Connectivity Issues Physical and environmental factors, such as remote locations, large distances, and harsh industrial conditions, can pose significant challenges for establishing reliable network connectivity.

- Security Concerns The fear of cyber threats and data breaches can make companies wary of connecting their operations to the cloud. Ensuring robust security measures is crucial to gaining confidence in digital transformation.

How to Fix These Blind Spots

Understanding the root causes of these operational blind spots is just the first step. To transform and optimize your operations, it’s crucial to implement practical solutions that address these gaps. By leveraging the latest IoT and cloud computing technologies, companies can not only illuminate these blind spots but also gain a competitive edge. Here’s how you can start bridging the digital divide:

- Invest in Edge Devices and Sensors Retrofitting existing equipment with edge devices and sensors can bridge the gap between legacy systems and modern digital platforms. These devices capture vital data and enable real-time monitoring without the need for costly replacements.

- Leverage Gateway Solutions Using advanced gateways ensures secure and reliable data transmission from the shop floor to the cloud. These gateways can handle harsh industrial environments, ensuring consistent performance.

- Adopt Scalable Cloud Integration Partnering with cloud service providers like AWS and Microsoft Azure can facilitate scalable and flexible data management. Cloud platforms offer the necessary tools to store, process, and analyze vast amounts of data efficiently.

- Implement Data Aggregation and Visualization Tools Consolidating data from various sources into a unified dashboard provides a comprehensive view of operations. Visualization tools help identify trends, track key performance indicators (KPIs), and make data-driven decisions.

- Build In-House Expertise or Partner with Experts Developing internal expertise through training or hiring specialists can empower your team to manage IIoT projects effectively. Alternatively, partnering with experienced IIoT solution providers can offer the necessary support and guidance.

- Prioritize Security Measures Implementing robust cybersecurity protocols is essential to protect your data and build trust in digital transformation. Employing encryption, access controls, and regular security audits can mitigate risks and safeguard your operations.

- Demonstrate ROI with Pilot Projects Starting with small-scale pilot projects can help demonstrate the tangible benefits of connectivity. Successful pilots can build confidence and provide a clear ROI, encouraging further investment in digital transformation.

Closing the Gap on Data Blind Spots

- Real-Time Monitoring and Analytics Connecting operations to the cloud enables real-time monitoring and analytics, providing immediate visibility into equipment performance and operational conditions. This capability allows for swift intervention, minimizing downtime and optimizing efficiency.

- Predictive Maintenance By analyzing data patterns, predictive maintenance solutions can forecast equipment failures before they occur. This proactive approach reduces unplanned downtime, lowers maintenance costs, and extends the lifespan of assets.

- Enhanced Operational Efficiency Automating data collection and analysis streamlines workflows, reducing the reliance on manual processes. This not only improves accuracy but also frees up personnel to focus on more strategic tasks.

- Informed Decision-Making Access to real-time, accurate data empowers decision-makers to respond quickly to market changes, optimize resource allocation, and adjust production schedules. Data-driven decisions enhance agility and competitiveness.

Conclusion

Addressing the connectivity challenges and closing the gap on digital data blind spots is crucial for industrial operations aiming to thrive in today’s competitive landscape. By investing in edge devices, leveraging gateway solutions, adopting scalable cloud integration, and prioritizing security measures, companies can overcome these hurdles and unlock the full potential of data-driven decision-making.

For further information on how to implement these solutions and bridge the connectivity gap in your operations, consider reaching out to industry experts and exploring the latest IIoT technologies available. Closing your data blind spots can lead to improved operational efficiency, reduced downtime, and enhanced decision-making capabilities, ultimately driving your business toward greater success.