Imagine a world where every tool, machine, and piece of equipment in your manufacturing plant is effortlessly tracked, optimizing efficiency and ensuring safety. This is the promise of the Industrial Internet of Things (IIoT), bringing a variety of asset tracking options to your fingertips.

Quick Introduction to IIoT Infrastructure:

Most manufacturing data can be gathered from connected smart machines or IIoT devices like BLE beacons attached to assets. Your IIoT infrastructure not only helps gather and send data to the cloud, but also plays a role in locationing, for example via triangulation.

With so many IIoT technologies available, finding the perfect fit and infrastructure configuration might seem daunting. Let’s simplify the choices and explore how each option could fit into your manufacturing ecosystem.

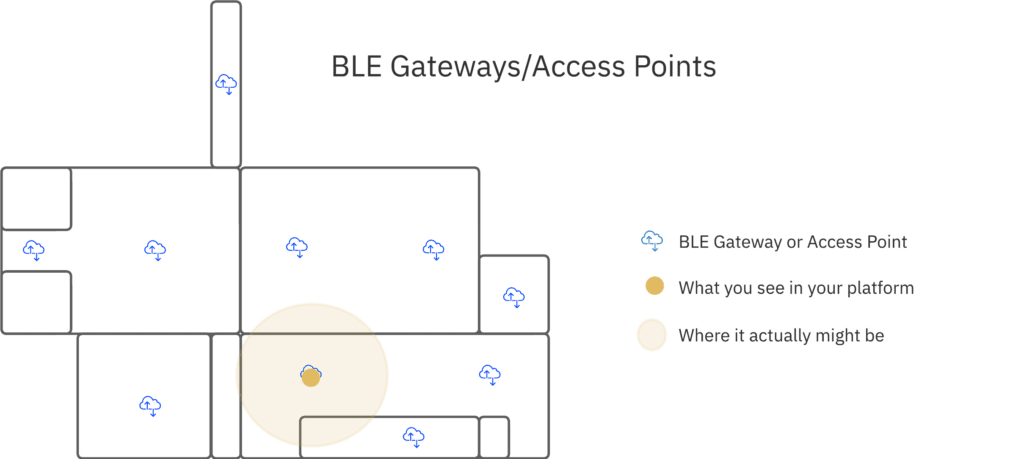

BLE Gateways/Access Points:

BLE (Bluetooth Low Energy) gateways/access points act like a bunch of digital lighthouses, casting connectivity across your facility and receiving signals from your connected assets. They’re great for tracking high-value tools and machinery, offering a sweet spot of flexibility and tracking capability. Ideal for environments where assets move around, these devices can cover significant ground, ensuring you keep a close eye on your valuable resources without going overboard. Depending on the density of your gateways and the range settings of your asset’s BLE signal, you might achieve room-level or facility-level accuracy. See the diagram below or check out this bluetooth range estimator tool. If using your existing access points, this can be a cost-effective way to get asset tracking up and running in your facility. The effectiveness of BLE tracking can be influenced by environmental factors such as physical obstructions, which may reduce signal range, and interference from other wireless devices. Planning the density and placement of gateways must account for these factors to ensure optimal coverage.

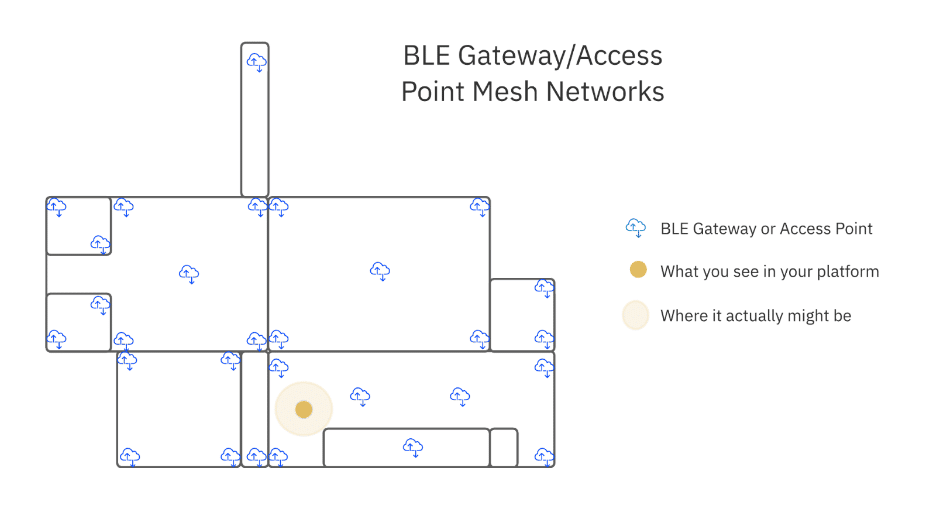

BLE Mesh Networks:

When you need to know the exact location of every asset down to a few feet, BLE mesh networks are the gold standard. Picture a tightly woven net of devices, each one communicating with the others to triangulate precise locations. This technology shines in large-scale operations where accuracy is paramount, from vast warehouses to sprawling manufacturing floors. The more gateways you add, the more accurate the triangulation becomes. This is valuable when the asset in question needs to be found quickly, i.e. a specialized tool that, if lost, halts production. This configuration is also valuable for accurate triggers and alerts or place-based analysis, i.e. to monitor when an asset is in a specific staging area within a room. To achieve this level of granularity, it is usually necessary to install a greater number of BLE gateways in addition to any pre-existing access points, and the more granularity needed, the more gateways needed. BLE mesh networks are sensitive to environmental conditions. Metal structures or heavy machinery can interfere with signal propagation, requiring strategic placement of nodes to mitigate these effects and maintain high precision.

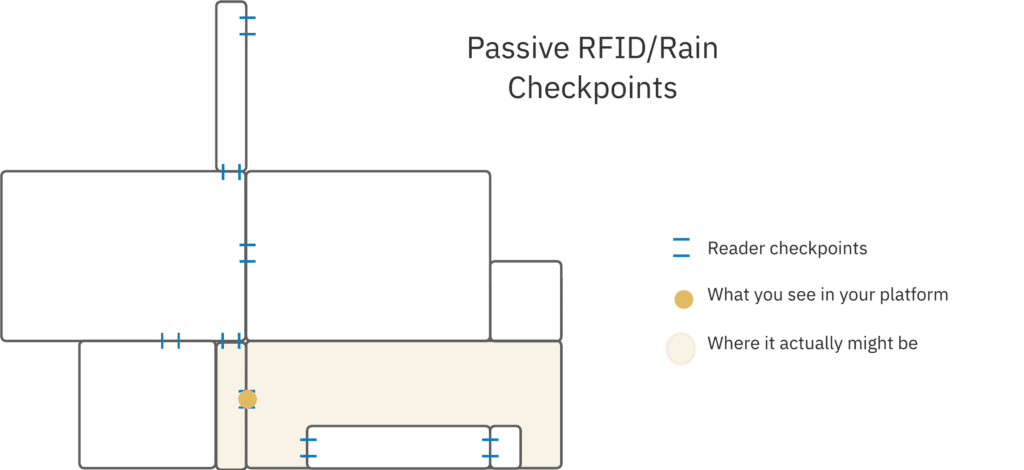

Passive RFID/RAIN Checkpoints:

Passive RFID is like setting up checkpoints or toll booths at strategic points in your operation. As assets pass through these points, they register their presence, offering a straightforward way to track movements. It’s a simple, effective solution for managing inventory or securing certain areas, tailored for operations that need basic tracking without the bells and whistles.The upfront cost of this infrastructure can often exceed that of active BLE tracking, without the benefits of real-time tracking. This use case is often ideal for very low value assets and in situations where BLE may be cost-prohibitive. The environment plays a crucial role in the deployment of RFID systems. Metal interference can significantly reduce the effectiveness of RFID tracking, necessitating careful planning of checkpoint locations to avoid signal disruption.

Barcode/NFC:

Barcode and NFC tracking require a personal touch, relying on manual scans to log asset locations. This method may work for smaller operations or those who require very granular (i.e. shelf-level) accuracy of very small assets in areas that signals cannot penetrate. While NFC operates at close range, typically less than 10 centimeters, it offers a reliable solution for tracking small assets in densely packed environments.

Manual Tracking:

The most traditional method, manual tracking, involves pen and paper or a basic digital spreadsheet, usually complemented by diligent record-keeping. While it’s the most labor-intensive and prone to errors, it’s often the starting point for operations that are either very small or not yet ready to invest in more advanced technologies.

Finding Your Fit in the Factory:

Choosing the right asset tracking technology boils down to understanding your operation’s specific needs:

- Scale and Complexity: Larger, more complex operations might lean towards BLE mesh networks for their precision, while smaller setups could benefit from the simplicity of using existing access points.

- Accuracy Needs: If exact location tracking is crucial, consider mesh networks. For less critical applications, standard BLE, RFID, or manual methods may suffice.

- Operational Flexibility: Operations with dynamic environments or those looking to scale might find the flexibility of BLE technologies particularly advantageous.

In Conclusion:

Selecting the ideal IIoT asset tracking solution for your manufacturing operation involves balancing your needs with the capabilities of each technology. From the high-tech, precise tracking offered by BLE mesh networks to the more labor intensive manual methods, there’s a tool for every job. The key is to match your choice to your operation’s size, complexity, and specific tracking requirements, ensuring your manufacturing process is as efficient and safe as possible.