Inventory management challenges create friction in the supply chain, leading to unnecessary costs and wasted resources. A well-implemented IoT solution with AI-powered analytics can address many of those challenges, leading to improved efficiency and better operations.

Common Inventory Management Challenges

Manufacturers of all sizes face a common set of problems:

- Inaccurate Inventory Data: There is limited visibility into the inventory on-hand.

- Manual Processes: Many manufacturers continue to use spreadsheets and other manual processes to count and track inventory. This is time-consuming and prone to mistakes.

- Lost or Misplaced Inventory Items: Inventory items are misplaced or lost through the warehouse. It can take hours, even days, to locate certain assets. Some are never recovered.

IoT and Analytics Solve Inventory Management Challenges

Manufacturers that implement an IoT-enabled digital transformation solution address these challenges. With IoT-enabled devices, they capture real-time data on inventory and other key assets. This offers three key benefits.

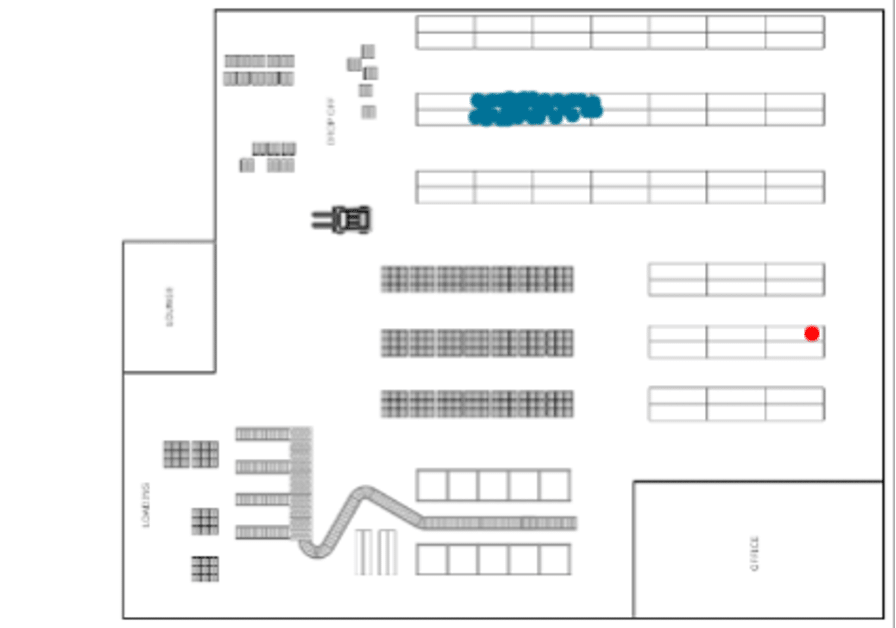

First, this provides both real-time location information on inventory items located throughout the facility. Second, AI-powered analytics models use this real-time data to create clusters of inventory items that are commonly placed together, providing a continuous inventory status. Finally, these models highlight outliers, making it possible to track location of missing assets in real-time. Misplaced assets trigger a real-time notification to warehouse operators. Therefore, this helps warehouse employees to track inventory and quickly recover lost objects.

This solution provides better data accuracy, automates manual processes, reduces lost or misplaced inventory items, and saves time. It resolves many inventory management challenges that manufacturers face.

Automate Processes