The defense manufacturing sector stands at the forefront of technological evolution.

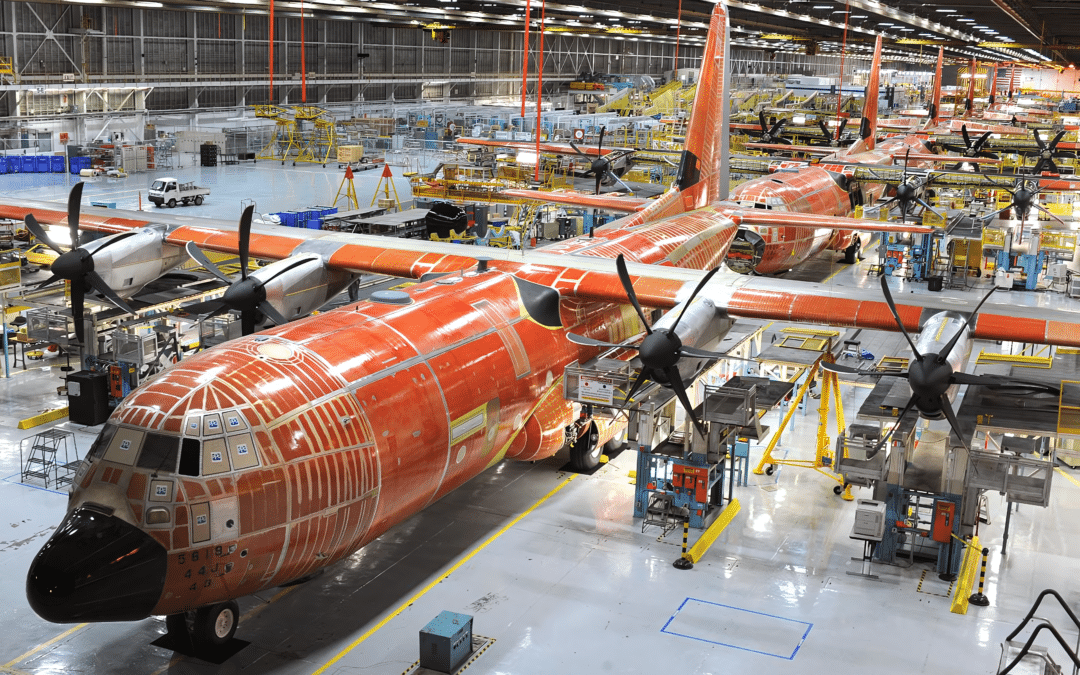

As geopolitical dynamics shift and the demand for innovative defense systems accelerates, manufacturers are under increasing pressure to produce more, faster, and better. The future of defense manufacturing isn’t just about building sophisticated systems—it’s about embracing Industrial IoT (IIoT), leveraging Smart Manufacturing technologies, and driving forward the principles of Industry 4.0 to create scalable, efficient, and resilient operations. At Thinaer, we’re not just champions of this evolution but participants with a footprint that spans over 12 million square feet of monitored industrial space and integrations across multiple states.

Thinaer is redefining what it means to operate at scale in the defense sector. Our solutions drive real-world impact by ensuring no downtime, maximizing Return on Investment (ROI), and reducing what we call “Go Find Times”—the speed and precision with which assets are tracked, located, and deployed. Here’s what defense manufacturers need to know about the future of their industry and how Thinaer is poised to lead the charge.

1. Embracing Scalability in Smart Manufacturing

In the defense sector, scalability isn’t just a convenience—it’s a necessity. Today’s manufacturers must manage facilities that rival the size of small cities while meeting stringent compliance requirements, integrating legacy systems, and maintaining zero error tolerance. Thinaer’s IIoT-powered platform monitors and optimizes sprawling industrial spaces, ensuring seamless operations across millions of square feet. Our solutions are designed to scale alongside your needs. Whether ramping up production on a new Department of Defense (DoD) contract or navigating the complexities of multi-site operations, Thinaer ensures that asset tracking, machine health monitoring, and operational visibility remain robust and actionable.

Why Scalability Matters: Defense manufacturers must contend with fluctuating demand, surging geopolitical pressures, and evolving DoD procurement requirements. Thinaer’s GovCloud-integrated solutions ensure secure and reliable data access, no matter the size or complexity of your operations.

2. The Industrial IoT Advantage: Driving ROI in Defense Manufacturing

For defense contractors, ROI often boils down to two critical metrics: increased production and no downtime. Every minute of operational disruption can cost millions in missed deadlines and unmet quotas. This is where Industrial IoT technologies shine. Thinaer’s IIoT platform integrates sensor data, machine learning, and real-time analytics to provide actionable insights that drive uptime and efficiency. By identifying potential machine failures before they occur or optimizing production workflows, we help defense manufacturers deliver on their production goals.

No Downtime, More Output: One of Thinaer’s key value propositions is our ability to prevent disruptions. For instance, with Amazon announcing they were sunsetting Amazon Monitron, Thinaer provided a cutting-edge alternative that ensures continuous monitoring and seamless integration with existing manufacturing infrastructures.

3. Industry 4.0 and the Defense Sector: The Smart Manufacturing Revolution

The principles of Industry 4.0—automation, data exchange, and the integration of cyber-physical systems—are transforming defense manufacturing. Thinaer enables manufacturers to adopt Industry 4.0 practices with minimal friction, combining the latest in cloud computing, edge devices, and AI-driven analytics to deliver unparalleled operational insight.

- Real-Time Insights: With Thinaer’s platform, defense manufacturers can access real-time data on everything from asset locations to equipment health. These insights empower teams to make informed decisions, allocate resources effectively, and reduce waste.

- Seamless GovCloud Integration: Thinaer ensures that all data is stored and processed securely, meeting DoD compliance standards while enabling seamless collaboration across stakeholders.

4. The Importance of “Go Find Times” in Asset Tracking

In defense manufacturing, time is often the most critical resource. Whether locating a specialized tool in a 500,000-square-foot facility or tracking the movement of sensitive materials between sites, speed and precision are paramount. Thinaer’s asset tracking solutions excel at reducing “Go Find Times,” allowing manufacturers to focus on production instead of searching for assets.

What Are “Go Find Times”?

It takes time to locate, retrieve, and deploy critical assets within your operations. For defense manufacturers, these times can mean the difference between meeting a tight deadline and facing penalties.

How Thinaer Delivers: Our platform uses IIoT sensors and advanced analytics to provide precise, real-time asset location data. In one instance, a defense manufacturer reduced their average Go Find Time by 15% after deploying Thinaer’s tracking solutions, freeing up hundreds of hours for value-added activities.

5. Data-Driven Decisions: The Role of Analytics in Defense Manufacturing

In today’s data-rich environment, having the right analytics tools is as important as having the right machines. Thinaer equips defense manufacturers with AI-powered analytics that transform raw data into actionable intelligence. Predictive Maintenance: One of the most immediate applications of analytics in defense manufacturing is predictive maintenance. By analyzing data from connected devices, Thinaer can predict when equipment will likely fail and recommend maintenance schedules that minimize downtime.

Production Optimization: Thinaer’s analytics tools also help manufacturers identify bottlenecks, optimize workflows, and streamline supply chain operations. For example, a defense contractor used our analytics platform to optimize assembly line configurations, resulting in a 3x increase in productivity in some cases.

6. Compliance and Cybersecurity: Navigating the DoD Landscape

Operating in the defense sector means navigating an intricate web of compliance requirements and cybersecurity challenges. Thinaer is uniquely positioned to help defense manufacturers stay ahead of these demands. With integrations across multiple GovClouds, our solutions are designed to meet the highest data security and regulatory compliance standards.

- GovCloud Advantages: Thinaer’s use of GovCloud ensures that sensitive data is handled securely, with robust access controls and encryption protocols. This is particularly crucial for defense manufacturers who must comply with stringent DoD cybersecurity mandates.

- Proactive Risk Management: Our platform continuously monitors for vulnerabilities and provides actionable recommendations to safeguard your operations.

7. Beyond a “Nice to Have”: Thinaer as a Mission-Critical Partner

In defense manufacturing, technological solutions aren’t just a “nice to have”—they’re mission-critical. Thinaer’s platform doesn’t just add incremental value; it transforms operations to deliver unparalleled efficiency, reliability, and scalability.

- High-Value Asset Tracking: With Thinaer, defense manufacturers can track high-value assets with precision, ensuring that every component, tool, and piece of equipment is where it needs to be when it needs to be there.

- Proven ROI: Our track record speaks for itself. From reducing downtime to optimizing production lines, Thinaer consistently delivers measurable ROI that justifies investment and builds long-term value.

The Road Ahead: What’s Next for Defense Manufacturing?

The future of defense manufacturing will be shaped by those who can adapt to rapidly changing technologies, regulatory landscapes, and market demands. At Thinaer, we’re committed to staying ahead of these changes, providing our partners with the tools they need to succeed. As we look to the horizon, integrating Industrial IoT, Smart Manufacturing, and Industry 4.0 principles will continue redefining what’s possible in the defense sector. Thinaer’s solutions—rooted in scalability, security, and actionable insights—position us as a trusted partner for defense manufacturers ready to embrace the future.

Final Thoughts: How Thinaer is Leading the Way

Defense manufacturing is entering a new era, one defined by unprecedented challenges and equally unprecedented opportunities. The companies that thrive will be those that invest in the right technologies, adopt data-driven practices, and prioritize scalability and resilience. At Thinaer, we’re not just observers of this transformation—we’re drivers of it. With our IIoT-powered platform, GovCloud integrations, and commitment to delivering measurable ROI, we help defense manufacturers achieve their most ambitious goals. Whether it’s increasing production, reducing downtime, or revolutionizing asset tracking, Thinaer is here to ensure your success. The future of defense manufacturing starts now.

Ready to Revolutionize Defense Manufacturing? Partner with Thinaer Today

If you’re ready to transform your defense manufacturing operations with the power of IIoT, Smart Manufacturing, and Industry 4.0, contact Thinaer today. Let’s build the future, together.