What is an IoT Network?

An IoT network is a system of interconnected devices, sensors, and machines that communicate through the internet to collect and exchange data. These networks use advanced protocols such as Long-Term Evolution for Machines (LTE-M), Narrowband Internet of Things (NB-IoT), and ultra-wideband (UWB) technology to facilitate seamless connectivity. IoT networks help businesses optimize logistics, monitor environmental conditions, and enhance operational efficiency. They also enable real-time tracking, automation, and predictive analytics, allowing organizations to improve supply chain management and business processes. Learn how IoT networks and connectivity platforms provide asset tracking, automation, and real-time feedback to streamline operations.

What is cellular IoT?

Cellular IoT technology introduces new opportunities for asset tracking and data collection. The technology connects “things” to the internet using the same networks that mobile phones use. As these networks improve and expand across the globe, more and more organizations are adopting this technology. In fact, Market and Research estimates that 4.15 billion people will be connected through cellular IoT by 2024.

Cellular IoT beacons, just like BLE beacons, make everyday objects ‘smart’ by connecting them to the internet. The technologies are similar; however, their situational capabilities differ. BLE beacons send data to Wi-Fi-enabled or cellular-enabled gateways, which are placed within indoor locations or plugged into vehicles. This makes BLE beacons ideal for indoor applications. Cellular beacons, on the other hand, use the same networks as mobile phones and work wherever there is cell service. They do not require a gateway to transmit data. As a result, they are great for outdoor applications.

There are two main types of cellular IoT: LTE-M and NB-IoT. The US, Netherlands, and Australia have national LTE coverage, which is compatible with LTE-M cellular IoT devices. GSM is the primary cellular network in Africa and Eastern Europe, which is compatible with NB-IoT cellular IoT devices. LTE-M cellular beacons easily interact with the cloud and are the best choice for real-time data transfer. NB-IoT cellular beacons, however, are best at transferring only small amounts of data at a time.

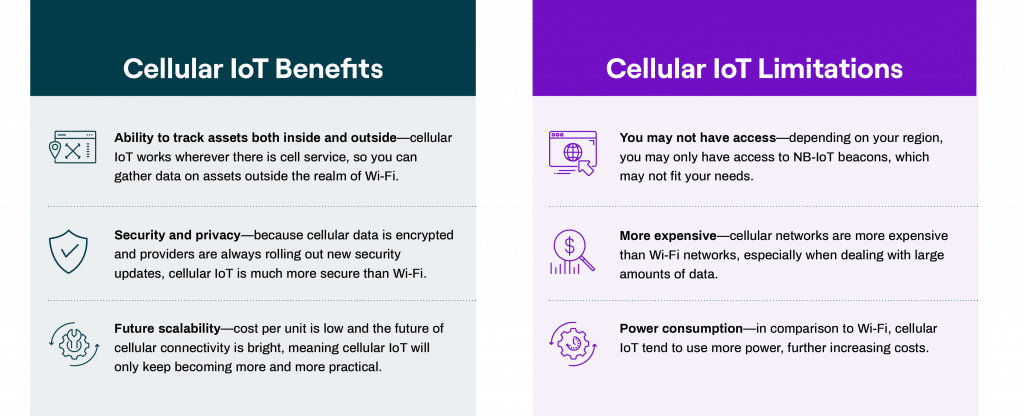

Benefits & Limitations of Cellular IoT

Like any technology, there are pros and cons to implementing this technology into your organization. It is important to consider where cellular IoT can enhance your operations as well as where it may fall short.

Benefits

-

Scalability – Cellular IoT works across vast geographic regions, allowing businesses to deploy tracking tags across the supply chain.

-

Low Power Consumption – NB-IoT and LTE-M technologies enable long battery life, reducing maintenance costs.

-

Enhanced Data Analytics – IoT data analytics provide deeper insights into supply chain trends, optimizing inventory management and logistics.

-

Improved Compliance – IoT protocols ensure regulatory compliance, particularly in pharmaceutical and automotive IoT industries.

-

Real-time Tracking – Businesses gain instant visibility into their assets, ensuring improved logistics and operational efficiency.

Limitations

-

Connectivity Dependence – Cellular IoT requires strong network coverage, which may be a challenge in remote locations.

-

Data Costs – Frequent data transmission can increase operational expenses if not managed properly.

-

Security Concerns – Organizations must implement robust IoT connectivity management platforms to safeguard sensitive data.

-

Limited Bandwidth – Cellular IoT networks are optimized for small, infrequent data transmissions rather than high-bandwidth applications.

Like any technology, there are pros and cons to implementing this technology into your organization. It is important to consider where cellular IoT can enhance your operations as well as where it may fall short.

How Companies Use Cellular IoT in Supply Chain Optimization

Supply Chain Visibility

Many firms use cellular beacons to track high-value goods and other items through the supply chain. Beacons capture real-time location, vibration, movement, and other data. With this information, companies pinpoint asset location, identify potential delays, and confirm proof of delivery. Over time, companies implement advanced analytics modeling to derive additional insights from supply chain data:

- Supply Chain Route Optimization – Evaluate location data to identify the most efficient delivery routes.

- Vibration Analysis – Detect sources of damage during shipment using vibration sensors.

- Root Cause Analysis – Combine location and employee feedback data to improve workflows and reduce inefficiencies

Cold Chain Monitoring

Cellular beacons provide real-time tracking of temperature-controlled products like food, medicine, and chemicals. If temperature or other environmental conditions trend out of compliance, IoT platforms are configured to send a detailed alert. This allows firms to take immediate action and prevent product spoilage.

Smart Warehousing and Automation

Modern warehouses are increasingly adopting automation in manufacturing using cellular IoT. IoT for manufacturing solutions improve logistics efficiency by automating tracking, inventory updates, and demand forecasting. Smart sensors and ultra-wideband (UWB) technology help businesses manage warehouse space more effectively, reducing downtime and improving order fulfillment accuracy.

Outdoor Air Quality Monitoring

Cities use cellular IoT beacons to capture and evaluate outdoor air quality at street level. This provides city leaders with data and insight to inform policy, map transit routes, and more. In addition, companies use a mix of BLE and cellular beacons to create a comprehensive campus air quality map. Together, the beacons monitor particular matter both indoors and outdoors, providing data to enhance employee safety, comply with environmental regulations, and even plan for building maintenance needs.

Digital Twin and IoT in Manufacturing

Businesses are incorporating digital twin supply chain models with IoT for manufacturing to simulate operations and predict maintenance needs. Digital twin companies utilize IoT connectivity platforms to enhance factory performance, reduce waste, and improve efficiency.

Ultra-wideband (UWB) technology plays a crucial role in tracking assets with high precision, particularly in automation in manufacturing. Real-time feedback loops using IoT connectivity management platforms further enhance predictive maintenance strategies, ensuring seamless production workflows.

5G and IoT: The Future of Supply Chain Optimization

The integration of 5G and IoT is expected to revolutionize supply chain operations by enabling ultra-fast data transfers, enhancing IoT in automotive industry applications, and improving IoT connectivity platform capabilities. This convergence will allow businesses to leverage real-time insights and optimize decision-making at every stage of the supply chain.

Optimize your supply chain with Thinaer’s fully intelligent IoT platform

Leverage Thinaer’s intelligent IoT platform for advanced supply chain optimization, enhanced IoT data management, and cutting-edge tracking tags technology. From ultra-wideband (UWB) technology to real-time feedback solutions, our platform provides actionable data to streamline logistics and improve operational efficiency.

Contact us today to transform your supply chain with IoT!

Frequently Asked Questions (FAQ)

How can you check data on devices connected through an IoT network?

Data from IoT-connected devices can be accessed through cloud-based IoT connectivity platforms. These platforms aggregate sensor information, provide real-time analytics, and enable businesses to monitor performance, track assets remotely, and optimize workflows efficiently.

What are the primary differences between LTE-M and NB-IoT?

LTE-M supports higher bandwidth and real-time data transfer, making it ideal for applications requiring instant feedback. NB-IoT, on the other hand, is optimized for low-power, long-range transmissions and is best suited for applications like environmental monitoring and asset tracking.

How does cellular IoT enhance automation in manufacturing?

By enabling predictive maintenance, real-time tracking, and digital twins, cellular IoT improves efficiency in manufacturing. It helps reduce machine downtime, optimize workflows, and enhance overall productivity.

Why is ultra-wideband (UWB) technology important for IoT?

Ultra-wideband (UWB) technology provides precise location tracking, making it a crucial component in real-time asset tracking, smart warehousing, and logistics optimization.

How does 5G improve IoT applications?

5G enhances IoT by providing ultra-fast data speeds, lower latency, and increased device connectivity, allowing businesses to deploy more complex and high-performance IoT solutions.