Next-Gen Shipbuilding with Thinaer

Advancing Defense with Data-Driven Modernization and Complete Operational Visibility

Why Thinaer?

Shipbuilding is a complex, high-stakes process, requiring precision, efficiency, and adaptability.

In an industry where delays, lost assets, and manual errors can drastically affect timelines and costs, digital transformation is essential.

Thinaer’s operational visibility platform provides real-time visibility, actionable insights, and improved coordination, empowering shipyards to overcome these challenges.

Common Shipyard Challenges

Lost or Idle Assets

Employees waste valuable time searching for tools or materials, slowing progress.

Environmental Monitoring

Manual checks are prone to errors and time-consuming.

Unplanned Equipment Downtime

Legacy machines lack real-time condition data, risking production halts.

Material Tracking

Large yards struggle to track thousands of materials, leading to delays and spoilage.

Process Compliance

Ensuring strict quality standards while meeting regulatory requirements is a constant challenge.

Thinaer’s Operational Visibility Tools: The Missing Link

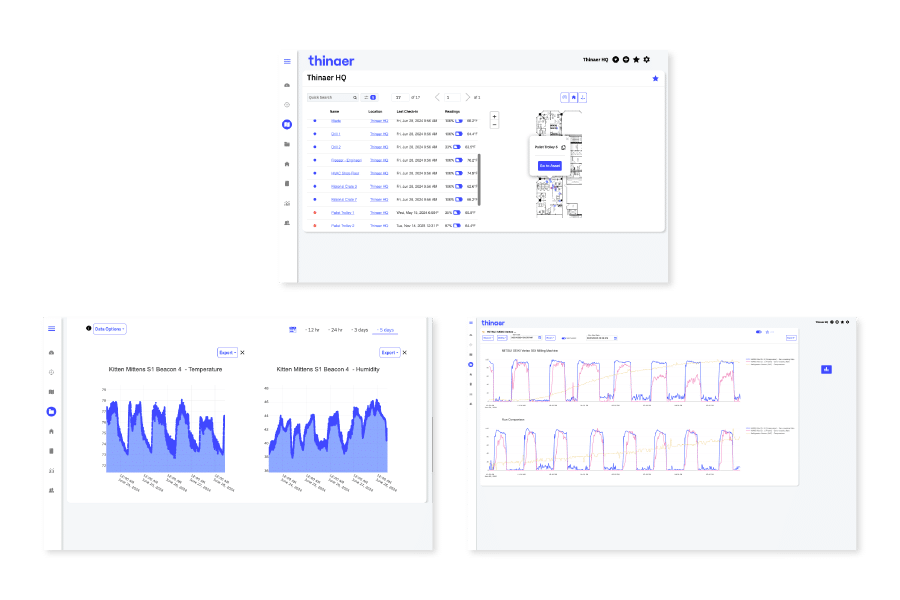

Asset Tracking

Real-time location data for tools and materials, reducing idle time and improving labor efficiency.

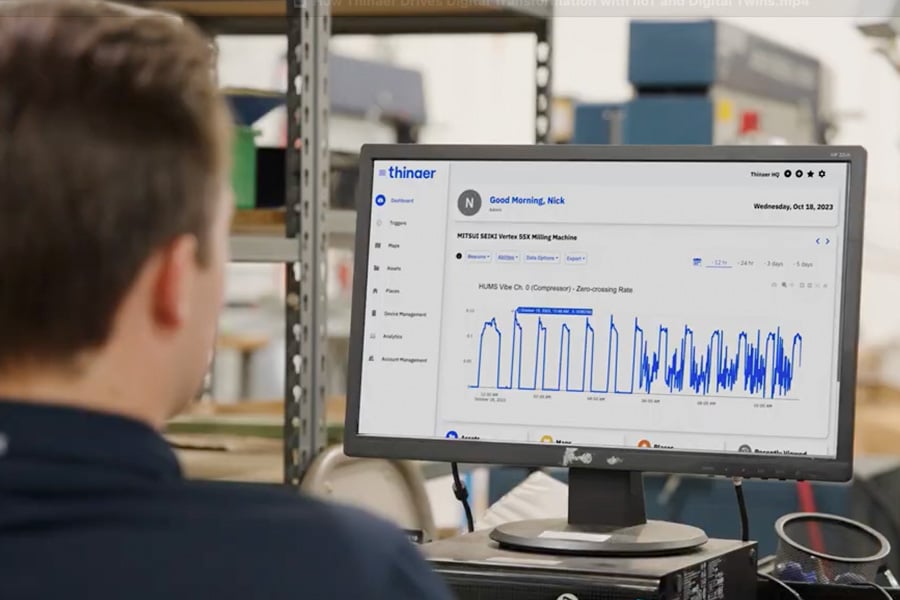

Machine Health

Predictive maintenance extends equipment life and reduces unplanned downtime.

Environmental Control

Automated monitoring ensures optimal conditions, maintaining quality and compliance.

Inventory Management

Track materials and supplies in real-time, preventing loss and ensuring availability.

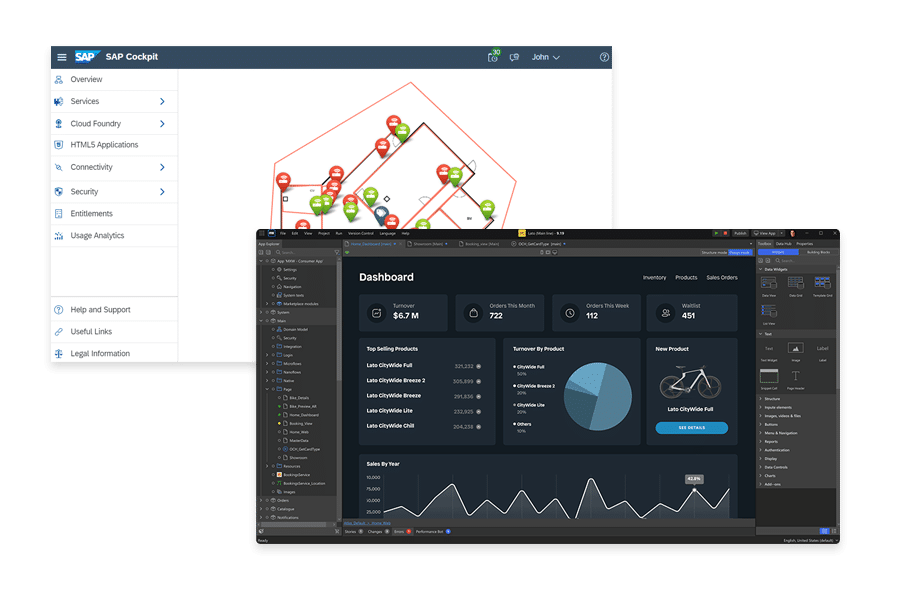

Thinaer’s Solutions Overview

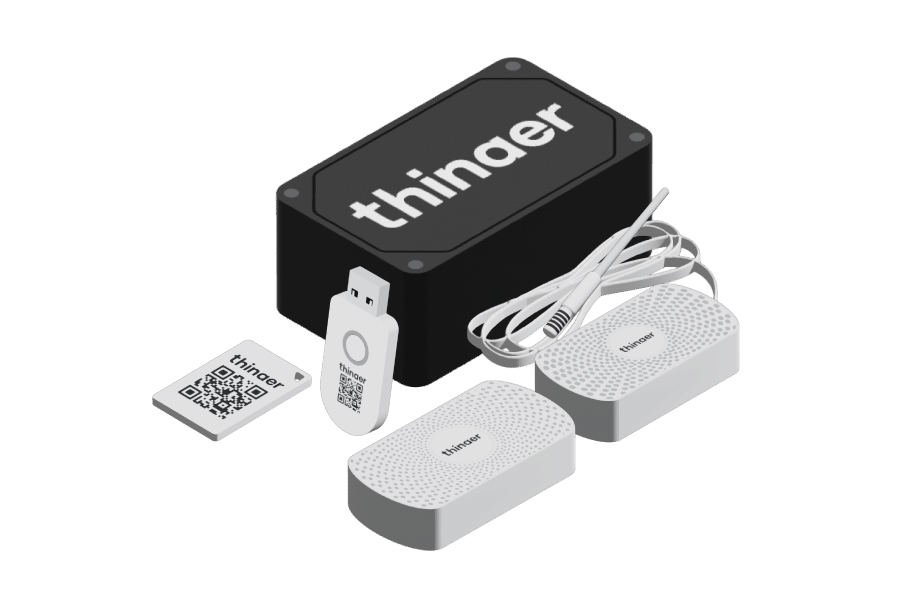

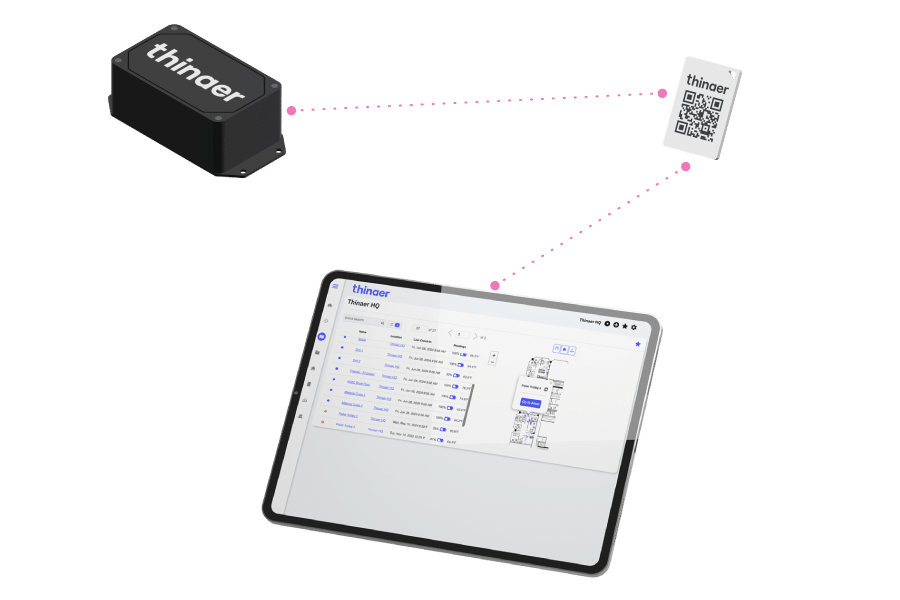

Thinaer provides an end-to-end IIoT platform that integrates asset tracking, environmental monitoring, machine health management, and inventory management into a single solution. Our platform is easy to deploy, scalable, and can be tailored to fit the specific needs of your shipyard.

Sensor Deployment

Attach IoT sensors to tools, machines, and materials.

Gather real-time data on location, environmental conditions, machine health, and material status.

Access data on a user-friendly dashboard with actionable insights to improve decision-making.

How It Works

Industries Served

Aerospace

Defense

Manufacturing

High-Tech

Energy

FAQs for Shipbuilders

How secure are your sensors?

At Thinaer, protecting your data isn’t just a compliance checkbox—it’s fundamental to how we operate. We’re committed to securing your sensitive information at every step, providing powerful insights without compromising security or agility.

De-Identified Data at Source:

Thinaer’s IoT sensors collect and transmit fully de-identified data packets. We intentionally exclude identifying information at the source, reducing risk exposure right from the start.

Secure Data Association Behind Your Firewall:

Data remains anonymous during transit and is only associated with identifiable systems or sensitive processes once securely behind your organization’s firewall. This design ensures maximum protection within your secure environment.

Dedicated, Secure Infrastructure:

Our solutions utilize secure and purpose-built communication infrastructures, ensuring your data remains protected, isolated, and resistant to unauthorized access or interference.

End-to-End Security Commitment:

Security is embedded throughout our technology and processes, aligning with industry-leading cybersecurity best practices and rigorous standards. Our approach provides peace of mind, enabling your organization to focus on actionable insights.

With Thinaer, you’re assured that your sensitive data—whether regulated or proprietary—is safeguarded with clarity, consistency, and integrity.

How rugged are the sensors?

Our sensors are designed to withstand harsh environments, including extreme temperatures and metal interference, ensuring reliable performance even in shipyard conditions.

Can Thinaer integrate with our existing systems?

Yes, Thinaer’s platform can integrate with ERP systems (e.g., SAP), providing seamless data flow and automation for inventory and process management.

What if we need help implementing?

Thinaer’s team is available to guide you through deployment and integration. We provide full support to ensure smooth, hassle-free implementation.