Ensure Machine Health with a Digital Twin

Use Industrial IoT smart devices to connect your unconnected facilities and equipment to fill digital data blind spots.

Future Proof Your Investment in Legacy Equipment

Using smart devices and IIoT sensors, you can connect your unconnected equipment, augment smartness, and start collecting data that you’ve never had before. This data enables organizations to fill blind spots and build a next-gen data set for AI initiatives.

Digital Twin: Facility Monitoring

Track conditions across your facilities, in store rooms, freezers, and other areas where raw materials and components are required to maintain certain standards. Start collecting data on temperature and humidity to air quality and the existence of light; with Thinaer digital twin, new datasets are easy to obtain.

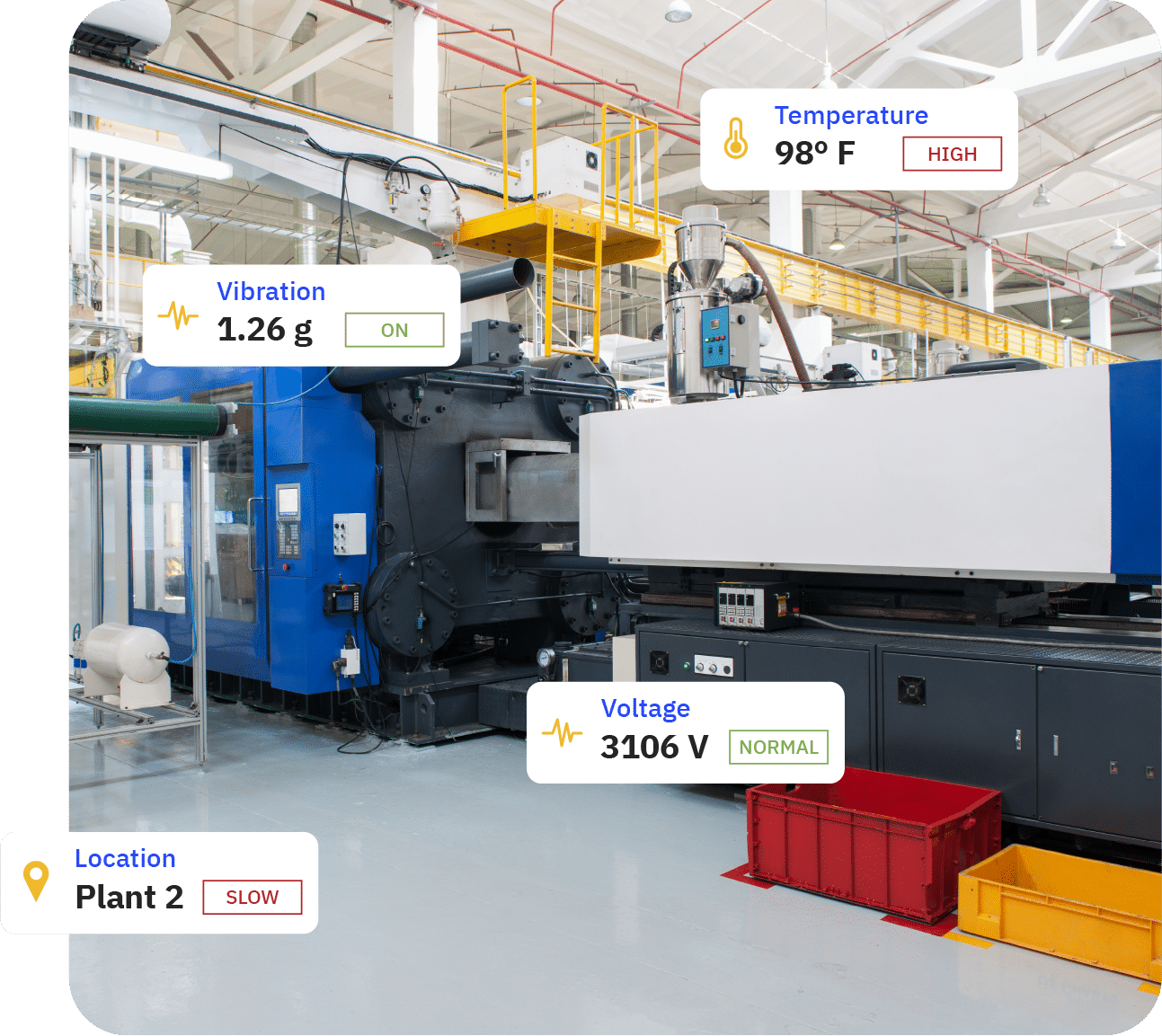

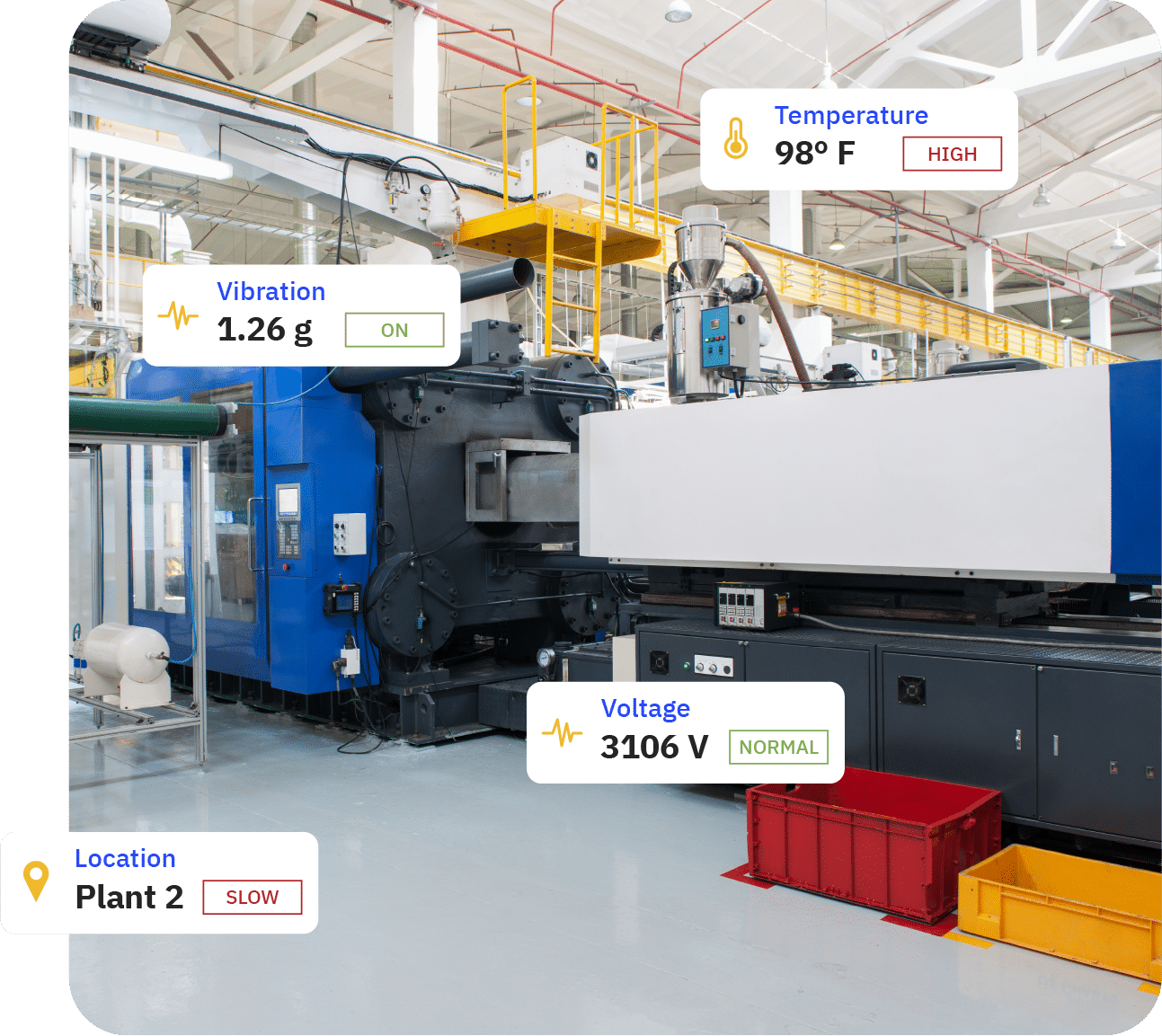

Digital Twin: Equipment Monitoring

Make legacy machinery connected by deploying smart sensors and beacons to replace analog data collection. With Thinaer equipment monitoring, you can manage and visualize equipment performance metrics in a single graph, normalize the data, and declare successful runs while comparing ongoing runs.

Real World Digital Twin Use Cases

Tracking Machine Utilization to Reduce Equipment Downtime for an Aerospace Manufacturer led to 15% less unscheduled equipment downtime

Precision monitoring raw materials to reduce waste for Manufacturing company resulted in 9% reduction in raw material waste

Find Your Blind Spots

Free 30-Minute Blind Spot Workshop

Discover how to gather data from IIoT, RFID, and even manual “blind spot” operations • Includes security tips • Learn benefits of tracking not just location, but real-time visuality into production • See how this data leads to smart predictions • Learn how to use AI to analyze your data • 11 techniques to uncover data in the 75% of your manufacturing that’s currently invisible • 5 ways to source the best transformative data partner • and more!