The global Consumer Packaged Goods (CPG) market is expected to realize a steady 3% CAGR and exceed $2.5 trillion by 2028 from $1.99 trillion in 2021. Like most every industry, CPG manufacturers face challenges in unpredictable shifts in supply and demand all the time. The solution to most of those challenges lies in intelligence.

At this scale, artificial intelligence (AI) is required to manage the complexity of data and systems, but AI success is directly proportional to the amount and quality of available data. The promise of digital transformation projects and the value of Industry 4.0/Smart Manufacturing also relies heavily on the amount and quality of available data. Thin margins, globalization, and high consumer demand raises the ante even higher.

Here are just four challenges facing CPG manufacturers today:

- Unpredictable shifts in supply and demand impact production planning

CPG production planning is complex. Mapping changes in consumer demand to the availability of raw material supplies becomes an almost impossible exercise when confronted with the unpredictability of environmental, sociopolitical, and global health care issues. While enterprise resource planning (ERP) systems have historically helped, the growing complexity of these unpredictable impacts has risen beyond the limitations of ERPs. This is where the combination of AI with IIoT can provide better answers. - Low end-to-end visibility due to lack of asset tracking and providence

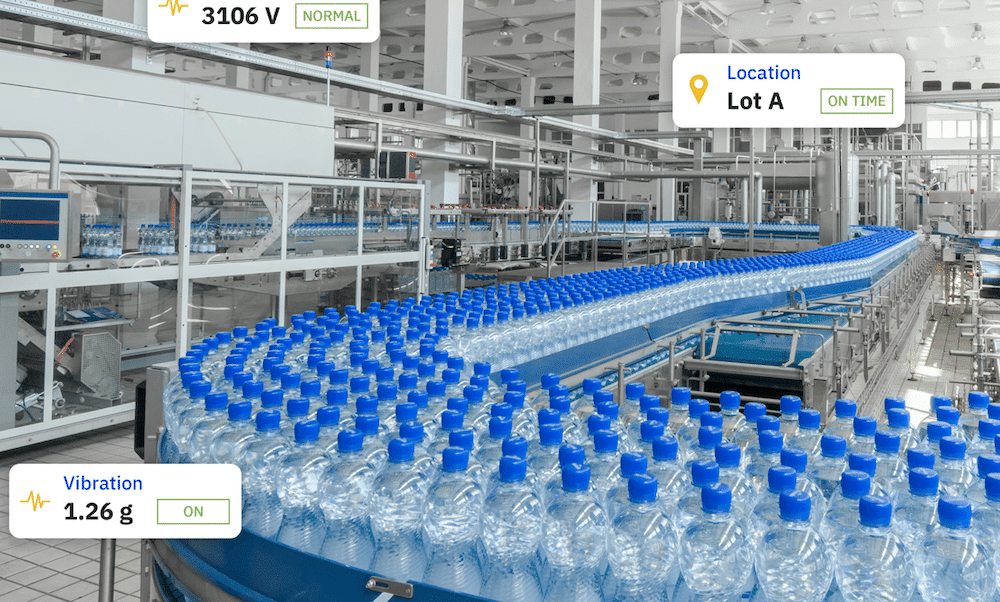

CPG manufacturers need visibility into inventory, providence, and material flows. It is critical to ensure product consistency, quality, and timely demand requirements. Any variation may compromise quality, profitability, and/or safety to finished goods. Knowing where raw materials through to finished goods are throughout the production process can mean the difference between operation efficiency and production yield or escalating waste and potential recalls. New IIoT technology can be deployed to provide granular and contextualized data on the location and history of critical assets in real-time. - Meeting quality assurance standards

CPG manufacturers should not allow the minutia of manufacturing to result in lower quality. Individual supplies are expected to be delivered to rigorous providence standards and without delay. To maintain finished goods quality, raw materials and environmental conditions must be tracked and accounted for at a granular level as much as equipment needs to be maintained and kept operational without interruption. AI allows for detection of anomalies that can be caused by imminent equipment failure or changes in environmental conditions. - Ingesting large amounts of data while addressing data gaps

It’s no secret that the ability to ingest and analyze more timely data equates to better operational and production decisions. In a typical CPG plant, this data is so profound, proper analysis is far beyond manual scan. AI becomes the only way to realistically ingest and analyze it all without error (or going cross-eyed). Combined with IIoT asset tracking, digital-twin modeling makes possible great intelligence from far less real-world trial and error by filling in the gaps in digital data currently addressed with manual processes. A more complete overview can then be achieved with greater insight into yield, operating expense, and safety thanks to data history, semantic modeling, and data analysis.

These four CPG challenges are just the tip of the iceberg. The complexities are numerous, and the solution is greater than any single concept. By combing AI with IIoT you get AIoT.

AIoT Generates Data That Doesn’t Exist

The key to eliminating these four challenges is directly proportional to the amount of granular and contextualized data available to your AI initiatives. Implementing an AIoT solution will provide that critical data. Start by understanding your IIoT asset tracking and digital twin requirements to collect data on:

- Environmental conditions

- Asset location, history, and providence

- Equipment health

- Process health

If you are looking for an innovative solution for asset location tracking and digital twinning to combine with your current AI and cloud solution of choice, then look no further than Thinaer. There are multiple architectures available to accommodate the nuances of your specific CPG requirements and can even accommodate classified area processes when deeper privacy and security is required. We understand that the more comprehensive your data set, the better your AI initiatives will deliver on their promise as well as allowing operations executives to spot prevention opportunities before they become problematic.

Contact us today for your digital transformation data issues and understand where your manufacturing blind spots put your operations and production at most risk. Our experts are ready to answer all your questions and help you get a handle on your digital transformation processes and AIoT initiatives. If you prefer to research more on this topic then download our latest eBook titled “Track The Untrackable: How to fill manufacturing blind spots for better production decisions and the most complete data set for AI initiatives.”